Trusted by leading companies

Vacuum insulated packaging

- Trusted Cold Chain

- Sustainable Performance

- Custom-Built Protection

High-performance thermal alternatives to vacuum insulation

For ultra-sensitive deliveries that demand maximum thermal protection, vacuum insulated packaging is often considered a benchmark in thermal efficiency. At Hydropac, we recognise the role of such innovations in the broader cold chain landscape. While we do not produce vacuum insulation panels (VIPs), our packaging systems are built to meet similar demands for performance, safety and temperature consistency across critical deliveries.

Using a combination of gel-based cooling, phase change materials and insulated containers, Hydropac delivers cold chain solutions that maintain stable internal conditions for extended periods. Whether used in pharmaceutical distribution, diagnostic transport or fresh food logistics, our passive thermal systems offer the reliability and protection needed in challenging environments.

Discover Vacuum insulated packaging

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Engineered for demanding deliveries

While VIPs serve very specific sectors, most temperature-sensitive goods are safely transported using validated, passive cooling systems. Hydropac designs packaging for these demanding conditions using high-grade insulation materials and advanced cooling elements such as HydroFreeze technology and EasiFreeze phase change packs.

Our systems are tailored for use in:

- Pharmaceutical logistics involving vaccines and insulin

- Diagnostic sample transport requiring stable conditions

- Frozen food and meal kit deliveries

- Clinical supplies and last-mile cold chain fulfilment

Hydropac’s thermal packaging is trusted for precision, hygiene and practicality across all key segments.

How Hydropac’s thermal protection works

Our insulated packaging limits heat transfer through carefully engineered materials that restrict conduction and reduce exposure to external temperature fluctuations. Although not vacuum-based, these systems perform exceptionally well in common cold chain temperature bands such as 2–8°C and below 0°C.

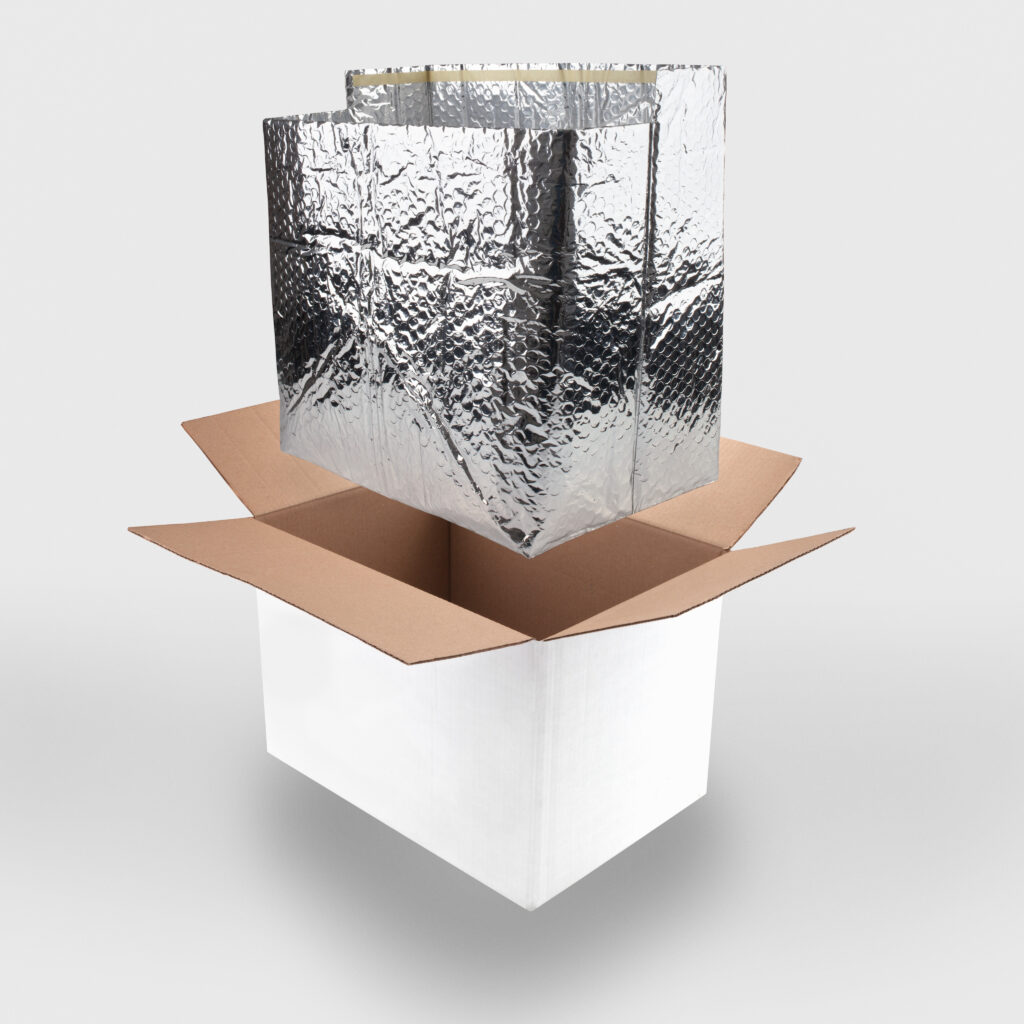

Typical configurations include:

- Expanded polystyrene (EPS) boxes with secure fitting lids

- Gel packs and water-based cooling packs matched to transit time

- Insulated pouches or liners for compact protection

- Outer cartons and labels designed for food or pharma compliance

Each solution is tested for thermal consistency and performance under varying ambient conditions.

Key benefits of Hydropac packaging systems

Compact and efficient formats

Our packaging is space-conscious without compromising insulation. From flat-pack inserts to stackable box systems, Hydropac solutions support effective loading and shipping.

Extended temperature control

Paired with HydroFreeze or EasiFreeze elements, our systems maintain stable internal temperatures for up to 72 hours or more depending on configuration and use case.

Cost-effective performance

Passive cooling systems reduce the need for heavy-duty refrigerants or complex handling protocols. This supports better operational efficiency and lower overall logistics costs.

Suitable for diverse environments

Hydropac solutions are routinely used in everything from last-mile delivery to overseas shipments, offering dependable protection even when external conditions vary widely.

Sustainability in focus

Many of our insulated packaging options are recyclable, reusable or built from recycled content. We continuously improve our material choices to reduce environmental impact.

Applications across critical sectors

Hydropac packaging supports industries that demand precision and reliability:

- PharmaPac systems for vaccines, insulin, and biological products

- FreshPac food packaging for chilled or frozen deliveries

- Laboratory samples and research materials

- High-value temperature-sensitive retail and subscription products

With robust construction and sector-specific compliance, Hydropac provides real-world alternatives to VIP-based solutions, without added complexity or cost.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about vacuum insulated packaging

What is vacuum insulated packaging used for?

It is used in highly specialised applications, such as investigational medicine or long-haul biologic shipments. Hydropac does not offer VIPs but provides proven alternatives for most pharmaceutical and food-related use cases.

How does Hydropac’s insulation compare to VIP panels?

While VIPs offer extremely low conductivity, Hydropac solutions use validated combinations of insulation and gel packs to meet similar temperature goals in a more scalable, cost-effective way.

Are Hydropac’s packaging solutions reusable?

Yes. Many of our boxes and ice packs are designed for reuse. Durability, ease of cleaning and repeat performance are all considered during development.

Can your systems be tailored to our cold chain requirements?

Absolutely. Hydropac offers custom sizing, branding and cooling configurations depending on your payload, transit time and compliance needs. Customised packaging is available without tooling costs for most solutions.

Why choose Hydropac instead of VIP systems?

For most logistics operations, VIPs are not required. Hydropac delivers high thermal performance with less complexity, making our packaging suitable for mainstream cold chain demands in both pharma and food.