Trusted by leading companies

Vaccine shipping solutions

- Precision Engineered Vaccine Packaging

- Consistent, High Quality Coolants

- Reliable Temperature Stability for Safe Delivery

Reliable Protection for Temperature Sensitive Vaccines

Vaccine shipping solutions are essential for safeguarding the potency and stability of temperature sensitive doses throughout their journey from production site to immunisation clinic. With strict temperature ranges and handling requirements, vaccines demand packaging that delivers consistency, reliability and full compliance at every stage of transport. Hydropac supports this mission with expertly engineered PharmaPac systems and precision cooled ice packs designed specifically for medical use. Through dependable insulation, validated cooling performance and hygienic manufacturing methods, vaccine shipping solutions help ensure that every dose arrives safe, effective and ready for administration.

Discover Vaccine shipping solutions

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Protecting Vaccines Through Every Mile of the Journey

Transporting vaccines requires a level of care and precision unlike any other product in the cold chain. These biological materials are highly sensitive to temperature fluctuations, handling delays and environmental conditions, which means every stage of the journey must be carefully controlled. Hydropac supports this vital process with specialised packaging solutions that uphold vaccine integrity, maintain stability and simplify compliance across complex distribution routes.

Why Vaccines Demand Exceptional Temperature Control

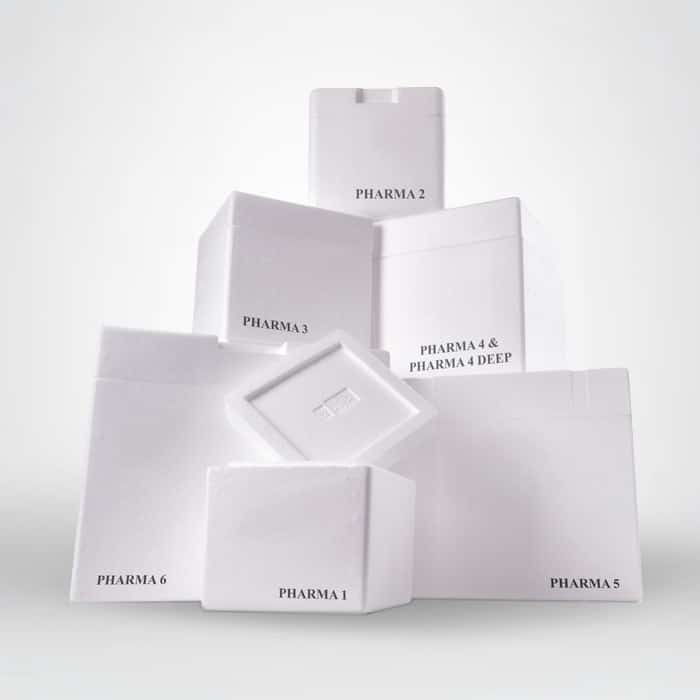

Vaccines remain effective only when stored within exact temperature ranges. Even short periods outside their required limits can reduce efficacy or lead to complete product loss. This is why organisations rely on high performance insulated packaging and coolant systems to create a stable internal environment during transit. Within the Hydropac PharmaPac range, vaccine shippers benefit from:

- Precision engineered gel and water based ice packs

- Reliable polystyrene and recyclable insulated containers

- Validated cooling profiles suitable for chilled and frozen vaccines

- Consistent thermal behaviour that supports regulatory compliance

These components work together to help safeguard doses from the point of manufacture through to healthcare providers.

Designing Packaging That Handles Real World Transport Conditions

Vaccines often travel long distances, moving through airports, warehouses, vehicles and clinical sites. During this journey, they face temperature variability, loading delays and changes in ambient humidity. Packaging must therefore be built to cope with real world conditions, not just controlled laboratory scenarios.

Hydropac’s manufacturing methods, including seal through water technology, create coolant packs with uniform thickness and dependable freezing performance. Paired with high quality PharmaPac insulated containers, these systems help maintain internal stability even during door openings, last mile delivery stages or unexpected handling variations.

Supporting Modern Vaccination Programmes

Vaccination schedules have grown increasingly demanding, with health systems requiring flexibility, rapid distribution and scalable logistics. Packaging plays a critical role in enabling outreach clinics, emergency deployment and routine immunisation. Vaccine shipping solutions must be lightweight for easy transport, robust enough for repeated handling and capable of maintaining temperatures for extended durations.

Hydropac’s product families offer options that suit a wide range of operating conditions, from routine delivery of refrigerated vaccines to the transport of more sensitive biological materials requiring lower temperature thresholds. This allows organisations to build reliable strategies for vaccination programmes of all sizes.

Creating Confidence Through Predictable Performance

Predictability is essential in vaccine logistics. Healthcare teams need confidence that their packaging will maintain temperature regardless of route, shipment size or climate. Hydropac designs its systems to deliver consistent performance, helping reduce wastage, improve operational efficiency and support safe vaccine administration.

Whether managing regional distribution or supplying clinical sites across wider healthcare networks, the combination of high quality packaging and dependable coolant technology helps ensure that vaccines arrive exactly as intended: stable, protected and ready for use.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's About Vaccine Shipping Solutions

What temperatures are required for transporting vaccines?

Most routine vaccines must be kept between 2 and 8 degrees Celsius throughout storage and transit. Some specialised vaccines may require frozen or deep frozen conditions. The exact temperature range depends on the product’s stability profile. Packaging systems must maintain this range consistently to protect vaccine potency.

What type of packaging is best for vaccine shipping?

Vaccines are typically transported in insulated containers supported by gel ice packs or water based ice packs. Hydropac’s PharmaPac systems combine high performance insulation with predictable cooling behaviour, making them suitable for maintaining vaccine temperatures during long and short distance transport.

How can vaccine shipments be protected from temperature fluctuations?

Reliable temperature control relies on three elements: high quality insulated packaging, properly conditioned coolant packs and correct packing procedures. Using validated packaging and ensuring ice packs are fully frozen before use helps reduce the risk of temperature excursions during handling or delivery.

Why is consistent cooling performance so important for vaccines?

Vaccines lose efficacy when exposed to temperatures outside their recommended limits. Consistent cooling prevents heat or cold damage, reduces wastage and supports safe administration. Packaging that delivers reliable thermal stability helps healthcare providers maintain the effectiveness of vaccination programmes.

How does Hydropac support vaccine logistics?

Hydropac provides precision engineered PharmaPac packaging with dependable insulation and high quality gel and water based ice packs. These solutions are designed to maintain strict vaccine temperature requirements across complex distribution routes, helping healthcare organisations deliver doses safely and confidently.