Trusted by leading companies

Vaccine cold chain logistics

- Validated Vaccine Packaging

- Sustainable Cold Chain Solutions

- ISO-Certified Performance

Precision, Safety and Trust in Every Degree

Vaccine cold chain logistics ensures that vaccines remain safe, effective and stable from production to patient. Every vaccine, from routine immunisations to advanced mRNA formulations, requires strict temperature control to preserve potency. At Hydropac, we understand the critical role of temperature management in healthcare logistics. Through our PharmaPac range, we provide validated temperature-controlled packaging solutions, including gel ice packs, insulated boxes and cold chain packaging systems, designed for the secure transport of vaccines and biologics. Manufactured under ISO 9001 standards, our products guarantee precision, hygiene and reliability, supporting the global delivery of life-saving vaccines with complete confidence.

Discover Vaccine cold chain logistics

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Building Resilient Cold Chains for Global Health

The integrity of vaccine cold chain logistics depends on one principle: maintaining precise temperature conditions from the point of manufacture to administration. Vaccines are highly sensitive to heat and freezing, with even minor temperature fluctuations risking potency loss. Reliable packaging, advanced insulation and validated refrigerants are therefore essential for safe distribution across healthcare networks, laboratories and international supply chains.

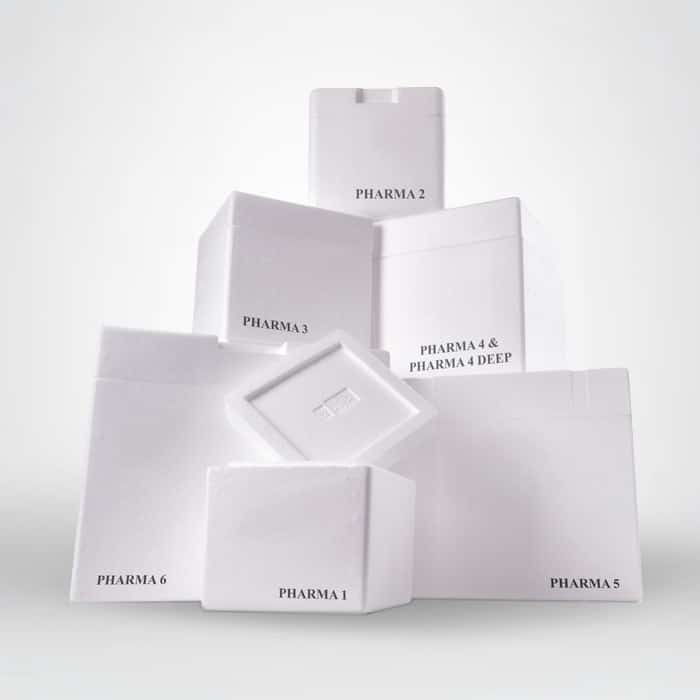

At Hydropac, we design cold chain solutions that combine advanced engineering with pharmaceutical compliance. Our PharmaPac range includes gel ice packs, polystyrene boxes, and insulated packaging designed specifically for vaccine storage and delivery. Every product is tested under simulated real-world conditions to ensure that critical temperature ranges are maintained, even during long transit times or in extreme climates.

Precision-Engineered Systems for Vaccine Transport

Our packaging systems are built to support the most demanding requirements of the vaccine supply chain. Each element of our design has been created to manage the risks associated with temperature-sensitive goods, while ensuring sustainability and regulatory compliance.

Key benefits include:

- Validated temperature performance for compliance with GDP and WHO vaccine storage guidelines.

- Seal-through-water technology for hygienic, leak-free cooling performance.

- Recyclable and eco-friendly materials supporting healthcare sustainability goals.

- Flexible temperature ranges, ideal for both refrigerated and frozen vaccines.

- Lightweight insulated materials for air freight, road transport and clinical distribution.

Hydropac’s innovation extends beyond cooling efficiency. We continuously test and validate materials to ensure they align with Good Manufacturing Practice (GMP) standards and UK healthcare regulations. Our insulation products, such as PharmaPac Polystyrene Boxes, deliver proven temperature stability and superior insulation for vaccine transport.

Sustainable Solutions for a Smarter Cold Chain

As healthcare evolves, sustainability is becoming a core requirement within vaccine logistics. Hydropac’s eco-friendly insulated packaging options, including systems derived from our RecycleAir and ReflectiveAir technologies, allow for reduced environmental impact without compromising thermal protection. We also offer solutions for temperature ranges refrigerated at 2-8 degrees.

Our long-standing expertise in temperature-controlled logistics ensures that every vaccine shipment remains secure, compliant and effective. By combining validated insulation materials, precise engineering and sustainable design, Hydropac continues to support healthcare providers and pharmaceutical manufacturers in protecting global immunisation efforts.

For more information on validated pharmaceutical packaging, visit the PharmaPac range.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about Vaccine Cold Chain Logistics

What is vaccine cold chain logistics?

Vaccine cold chain logistics refers to the process of storing, transporting and distributing vaccines within specific temperature ranges to maintain their potency. It involves specialised packaging, refrigeration and monitoring systems to ensure vaccines remain safe and effective until they reach healthcare facilities.

Why is temperature control so critical for vaccines?

Vaccines are biological materials that can degrade when exposed to incorrect temperatures. Most require storage between 2°C and 8°C, while some, such as mRNA vaccines, need ultra-cold conditions below -70°C. Hydropac’s PharmaPac range, including PharmaPac Polystyrene Boxes, provides the insulation and stability needed to maintain these critical temperature conditions.

How does Hydropac ensure reliability in vaccine transport?

Hydropac manufactures temperature-controlled packaging that meets ISO 9001 standards and aligns with GDP and WHO guidelines. Each product undergoes thermal testing to validate performance under real-world conditions. Features such as seal-through-water manufacturing and recyclable materials enhance both reliability and sustainability.

Can Hydropac packaging be used for international vaccine shipments?

Yes. Our packaging systems are designed to perform under varying transport conditions, including air freight, sea freight and road distribution. The lightweight insulation used in solutions such as PharmaPac ensures compliance with airline regulations while maintaining efficiency and stability across long-distance vaccine logistics.

What makes Hydropac’s vaccine packaging environmentally responsible?

Sustainability is central to our innovation. Hydropac integrates recyclable and biodegradable materials in its temperature-controlled packaging, such as those found in the FreshPac ReflectiveAir System. These materials minimise environmental impact while preserving high thermal performance, supporting global efforts toward greener healthcare logistics.