Trusted by leading companies

Temperature controlled vaccine transport

- Validated pharmaceutical compliance

- Sustainable cold chain packaging

- Proven vaccine temperature control

Safeguarding Vaccine Integrity Through Reliable Cold Chain Systems

Temperature controlled vaccine transport is critical in ensuring that vaccines remain safe, stable, and effective from production to administration. Even minor temperature deviations can compromise a vaccine’s potency, making reliable cold chain systems essential to public health and global immunisation efforts. Hydropac provides expertly engineered packaging solutions designed to maintain strict temperature ranges throughout transit. Our PharmaPac range, featuring precision-tested gel ice packs and insulated shipping boxes, ensures compliance with regulatory standards while reducing waste and environmental impact. With Hydropac, healthcare providers and pharmaceutical distributors can transport vaccines with confidence, reliability, and sustainability.

Discover Temperature controlled vaccine transport

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Precision and Reliability in Vaccine Transport

In the pharmaceutical industry, maintaining vaccine stability throughout storage and transport is a non-negotiable requirement. Vaccines are biological products that can lose their effectiveness if exposed to incorrect temperatures, making temperature controlled vaccine transport a cornerstone of successful immunisation programmes worldwide.

Hydropac’s expertise lies in creating high-performance, compliant packaging systems that ensure vaccines remain within their required temperature range, whether chilled, frozen or ultra-low.

The Science Behind Reliable Vaccine Transport

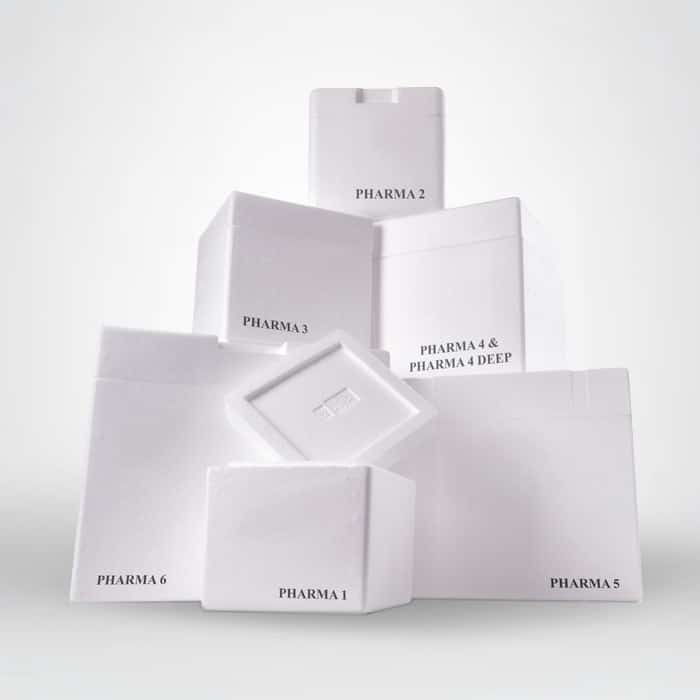

Our PharmaPac packaging range is engineered to deliver consistent performance across a variety of conditions. Every component is tested to meet the standards set by regulatory frameworks such as EU GDP guidelines and WHO Annex 9.

Key factors include:

- Thermal integrity: Maintains precise temperature ranges from +2°C to +8°C or frozen conditions below -18°C.

- Validated materials: Our gel ice packs and polystyrene boxes undergo rigorous performance testing under real-world scenarios.

- Safe conditioning methods: Designed to prevent temperature shock or product freezing during transit.

- Hygienic manufacturing: All packaging is produced in controlled environments using our seal-through-water technology for a secure, leak-proof finish.

Sustainable and Compliant Cold Chain Solutions

Hydropac combines temperature control with environmental responsibility. Many of our ice and gel packs are fully recyclable and drain-safe, while packaging materials are chosen for their reduced carbon footprint. This allows clients to meet sustainability targets without compromising on pharmaceutical safety.

Our cold chain systems are used for transporting:

- Routine and emergency vaccines

- Biological samples and medical reagents

- COVID-19 and mRNA-based vaccines

- Insulin, bloods, and temperature-sensitive pharmaceuticals

The Future of Safe Vaccine Delivery

As global healthcare systems evolve, the demand for reliable, traceable and sustainable cold chain infrastructure continues to grow. Hydropac supports this shift through innovation and ongoing research, ensuring that every shipment arrives in optimal condition – from manufacturer to medical facility.

Our temperature controlled packaging solutions provide the foundation for dependable vaccine transport that meets both regulatory compliance and environmental responsibility goals.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about Temperature Controlled Vaccine Transport

Why is temperature control so critical in vaccine transport?

Vaccines contain biological materials that are highly sensitive to temperature changes. If exposed to conditions outside their recommended range, their potency and effectiveness can deteriorate. Maintaining a stable cold chain ensures that every dose remains safe and fully effective upon delivery.

What temperatures are required for vaccine storage and transport?

Different vaccines require specific temperature ranges depending on their formulation. Most vaccines are stored between +2°C and +8°C, while some, such as mRNA vaccines, may require ultra-cold conditions below -70°C. Hydropac’s packaging is designed to meet these diverse temperature requirements reliably.

How does Hydropac ensure compliance with pharmaceutical transport standards?

Hydropac’s PharmaPac range is engineered to meet global compliance standards such as EU GDP guidelines and WHO regulations for vaccine distribution. Every product undergoes rigorous validation testing to guarantee temperature stability, hygiene and durability throughout the logistics process.

Are Hydropac’s packaging solutions environmentally friendly?

Yes. Hydropac integrates sustainability into every stage of production. Many of our gel ice packs are recyclable and water-safe, while our packaging materials are chosen for their low environmental impact. We are committed to reducing waste and supporting a more sustainable pharmaceutical cold chain.

What types of vaccines or medical products can be transported with Hydropac solutions?

Hydropac’s temperature controlled packaging can safely transport a wide range of vaccines and medical materials, including routine immunisations, COVID-19 vaccines, biological samples, insulin, and blood products. Each solution is custom designed to maintain integrity across temperature-sensitive pharmaceutical applications.