HydroFreeze™ and HydroFreeze™+ are our ice packs containing a unique food safe formula, designed to enable safer shipping of frozen goods. They work in the same way as dry ice, but are much safer as, unlike dry ice, HydroFreeze™ products are not classed as hazardous goods when shipping, and they do not require any specialist handling.

Both versions of HydroFreeze™ can maintain temperatures at -20°C for an extended period of time. It consists of only food approved, natural ingredients, found in your everyday life!

Regular water/gel ice packs phase change at 0°C (the freezing point of water) so once packed inside your insulated box, they will sit at around 0°C while changing from a solid back to a liquid. These regular water/gel ice packs should only be used for shipping chilled food as they phase change at 0°C – not cold enough for frozen food, but perfect for refrigerated goods. HydroFreeze™ products have a phase change point of -20°C, which means they hold that temperature while changing from a solid back to a liquid – and hold the food products inside the insulated box at around the same temperature.

What is the difference between HydroFreeze™ and HydroFreeze™+?

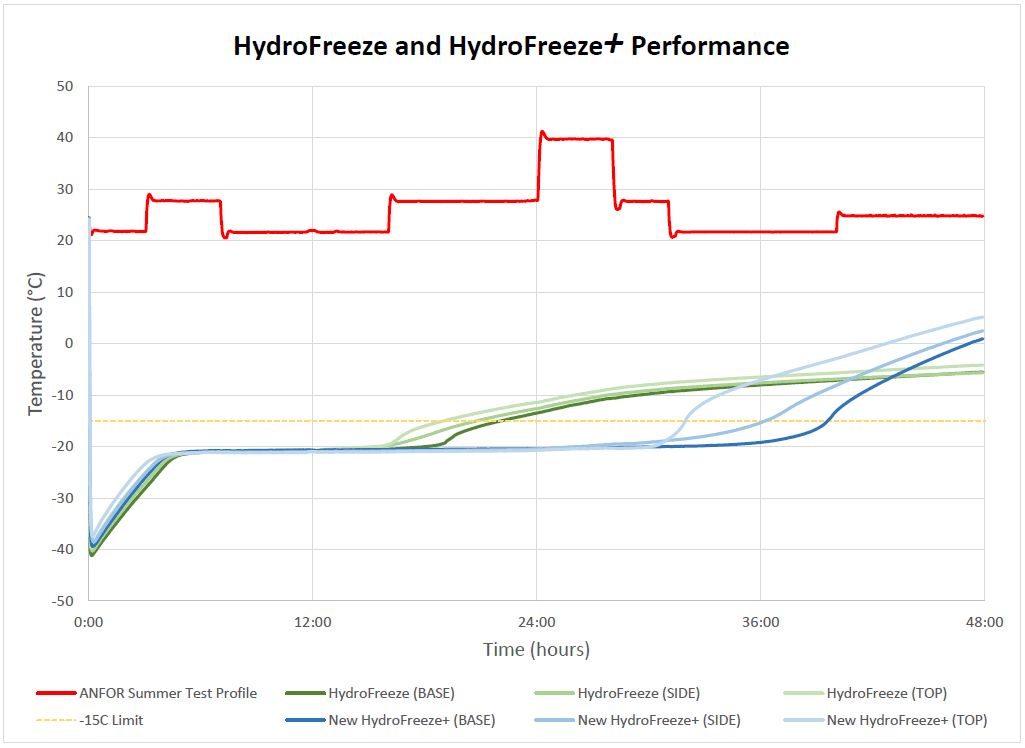

HydroFreeze™ is a formula designed to phase change at -20°C. When frozen correctly and packed in a good quality insulated box, these ice packs can be used to hold frozen food at a temperature of below -12°C for approx. 24 hours.

HydroFreeze™+ is our newly developed gel formulation of the previous product and is designed to enable shipping of frozen goods for longer transit times. Like the regular HydroFreeze™ the new HydroFreeze™+ phase changes at -20°C and can hold food at around that temperature, but where HydroFreeze™+ really excels is in its longevity. The new HydroFreeze™+ ice packs will absorb a great deal more energy before they completely freeze, so will need to be in a powerful freezer or will take a longer period of time to freeze. However, once they are frozen and packed inside a suitable insulated container they will hold -20°C for approx. 24 hours or -15°C for approx. 36 hours.

HydroFreeze™ and HydroFreeze™+ can maintain temperatures at -15°C, however HydroFreeze™+ can hold that temperature for an extended period of time. Both of these products have been developed with safety, quality, performance and cost in mind, and consist of only food approved ingredients.

HydroFreeze™ and HydroFreeze™+ are produced in our state-of-the-art manufacturing facility in High Wycombe, Buckinghamshire, with the capacity to cater for all users looking for a safer and more economical solution to sending frozen goods.

Currently using Dry Ice?

Dry ice (solid CO2) is currently the most common consumable used for the shipping of frozen products; it maintains sub-zero temperatures through the process of sublimation - i.e. converting directly from a solid to a gas. Dry ice is classified as a miscellaneous hazard (Class 9) during transportation by DOT and IATA.

Hazards associated with dry ice include risk of explosion and suffocation in an enclosed space, and risk of severe frostbite injury when handled. Dry ice is so cold it will freeze the blood inside your skin if handled with bare hands. For these reasons, many carriers have now restricted or prohibited the distribution of parcels containing dry ice, and the couriers that do still accept it will apply a surcharge to the shipping cost.

HydroFreeze™ and HydroFreeze™+ eliminate these hazards and offer a safer and competitive alternative – think of it as a regular ice pack… just a cooler version of it!

So What are the Benefits of Using HydroFreeze™ and HydroFreeze™+

Recommended Pre-conditioning of HydroFreeze™ & HydroFreeze™+

* Freeze times are largely dependent on the freezer temperature and the quantity that is being frozen at that particular time (i.e. pallet load will take considerably longer to fully prepare compared to a single pack). Ensure sufficient cold air circulation around the product for efficient freezing and be aware they will take longer to freeze than normal water/gel ice packs.

Safety and Disposal Instructions

For more information

Call 01494 530182 or email us at sales@185.104.28.45/~hydropacold

So What are the Benefits of Using HydroFreeze™ and HydroFreeze™+

Differentiators

| Dry Ice | HydroFreeze™+ | Water/Ice | |

| Melting/Sublimation Point | -78.5°C | -20°C | 0°C |

| Amount of energy

(Below -15C)* |

571.3 | 347 | 136.5 |

| Classed as Hazardous Goods | Yes | No | No |

| Suitable for Frozen Goods | Yes | Yes | No |

| Cost Per Kg | From £1.00+ | From £0.86 | From £0.42 |

* Assuming theoretical start temperature of -80°C and 1kg of each

Comparisons:

| Dry Ice | HydroFreeze™+ | Water/Ice | |

| Melting/Sublimation Point | -78.5°C | -20°C | 0°C |

| Amount of energy

(Below -15C)* |

571.3 | 347 | 136.5 |

| Classed as Hazardous Goods | Yes | No | No |

| Suitable for Frozen Goods | Yes | Yes | No |

| Cost Per Kg | From £1.00+ | From £0.86 | From £0.42 |

* Assuming theoretical start temperature of -80°C and 1kg of each

Useful Test Graph

| FSA Temperature Control Guide | Download now |

Subscribe to the newsletter!

Be the first to know!

a member of the Bunzl group of companies

Design & development