Trusted by leading companies

Refrigerated packaging

- High Performance Chilled Packaging

- Consistent, Quality Controlled Coolants

- Reliable Protection for Temperature Sensitive Goods

Protecting Temperature Sensitive Goods with Confidence

Refrigerated packaging plays a vital role in maintaining the quality and safety of chilled foods, pharmaceutical products and other temperature sensitive goods during transit. By creating a controlled environment inside every shipment, these solutions help safeguard products from ambient conditions and handling variations. Hydropac supports this essential part of the cold chain with a wide range of insulated systems, from FreshPac food packaging to specialist PharmaPac solutions for medical use. With precision cooled gel packs, water based ice packs and sustainable insulated liners, refrigerated packaging ensures dependable performance from dispatch to delivery.

Discover Refrigerated packaging

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Keeping Products Fresh, Safe and Stable Throughout Transport

Refrigerated packaging is a cornerstone of modern cold chain logistics. It enables temperature sensitive goods to travel safely across varied environments, protecting quality, freshness and compliance at every stage. From gourmet foods and dairy products to pharmaceutical supplies and clinical materials, businesses rely on packaging systems that deliver reliable thermal stability. Hydropac supports this need with an extensive range of chilled packaging across its FreshPac, PharmaPac and Ice Packs by Hydropac families, each engineered to offer dependable performance in demanding real world conditions.

Why Refrigerated Packaging Matters Across Industries

The cold chain is expanding rapidly as consumers expect fresher foods, healthcare systems move delicate medicines through wider networks and online deliveries increase year after year. This growth makes temperature accuracy a priority. Refrigerated packaging helps maintain product integrity by controlling the internal thermal environment, reducing spoilage, preventing contamination and supporting regulatory compliance. Hydropac’s solutions are trusted by food producers, fishmongers, meal kit companies and healthcare providers who require packaging that performs consistently through every link in the chain.

How Hydropac Creates Reliable Thermal Protection

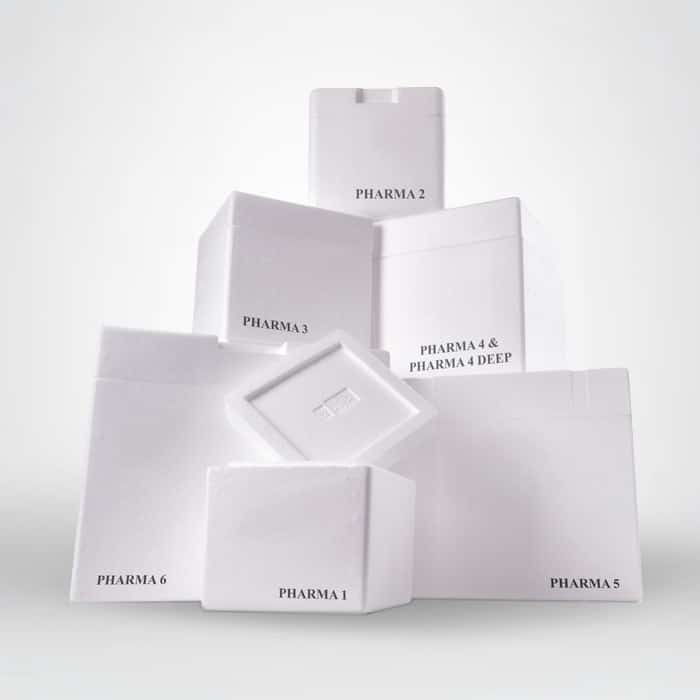

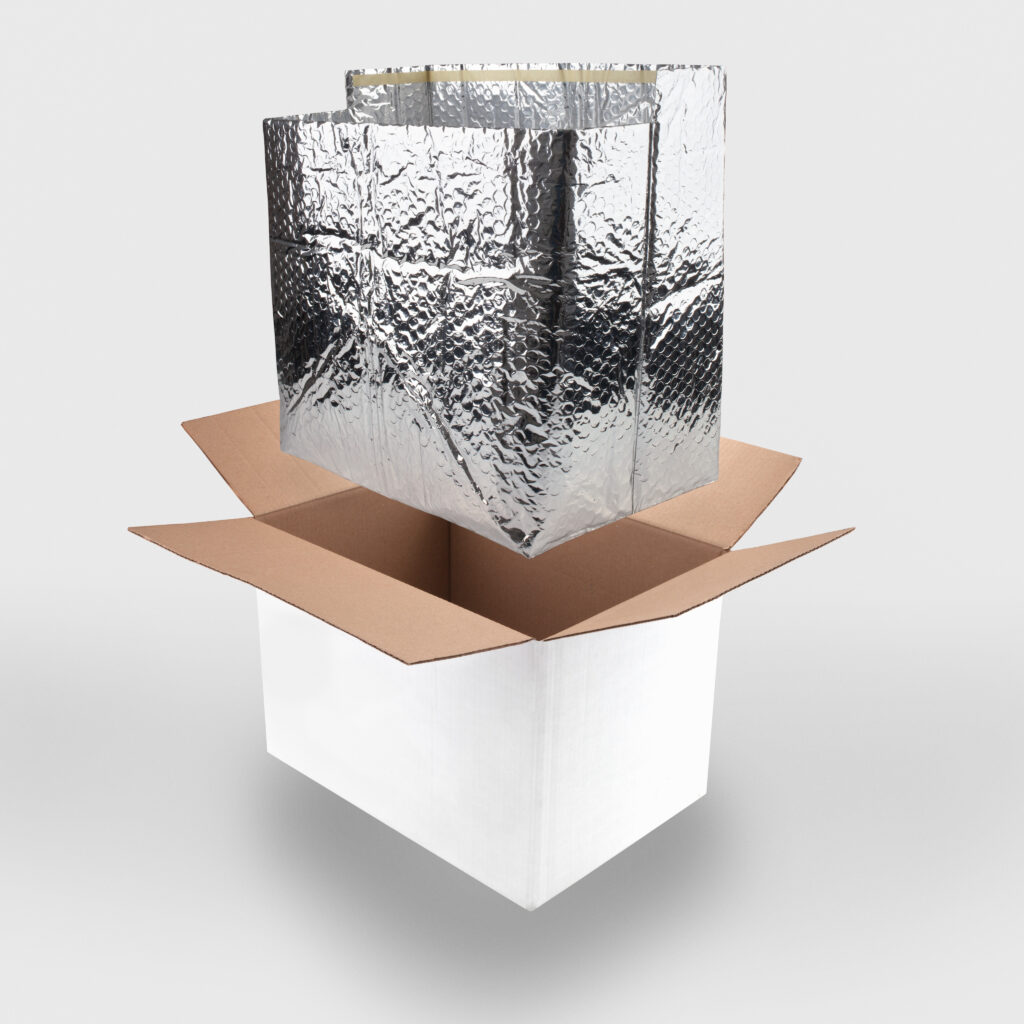

The effectiveness of refrigerated packaging depends on the quality of the insulation and the performance of the coolant. Hydropac combines high grade materials with specialist cooling technology to create packaging that is both efficient and easy to use. Across the FreshPac range, options like EnviroCool, RecycleAir and ReflectiveAir offer strong insulation with sustainable benefits. PharmaPac solutions provide pharmaceutical grade protection with polystyrene containers and precision cooled gel packs. Every system is designed to work harmoniously with Hydropac’s water based ice packs and gel formulations for stable temperature control.

Designed for Real Life Logistics Challenges

Shipments rarely travel in perfect conditions. They might sit briefly in warm loading areas, encounter delays or pass through multiple delivery points. Hydropac’s refrigerated packaging solutions are created with these real world scenarios in mind. They help maintain consistent temperatures by minimising heat transfer, maximising internal stability and supporting proper coolant placement. With manufacturing methods such as seal through water technology, Hydropac ensures reliable, hygienic and uniform coolants that freeze efficiently and behave consistently during use.

Choosing the Right Refrigerated Packaging

Every shipment has different requirements, whether you are moving fresh seafood, dairy, ready meals, vaccines or medicinal supplies. Selecting the right packaging involves more than simply adding ice packs. Businesses must consider factors such as duration of travel, expected ambient temperature, type of coolant and insulation level needed. Hydropac’s wide product range allows companies to choose solutions that match their exact requirements, helping them maintain cold chain integrity without adding unnecessary weight or complexity.

Key considerations include:

- Required temperature range, from chilled to frozen

- Transport duration and handling conditions

- Type of coolant needed, such as gel packs or water ice packs

- Level of insulation provided by liners or containers

- Sustainability goals and recyclable material preferences

By aligning these factors with the correct packaging solution, businesses can protect their products more effectively and improve overall delivery performance.

Supporting a Sustainable and Efficient Cold Chain

Refrigerated packaging not only preserves product quality but also plays a role in reducing waste and environmental impact. Hydropac’s sustainable solutions, such as RecycleAir and eco responsible insulated materials, help businesses lower their footprint without compromising performance. Combined with durable packaging that can be reused where appropriate, Hydropac supports both operational efficiency and responsible resource use across the cold chain.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's About Refrigerated Packaging

What is refrigerated packaging used for?

Refrigerated packaging is designed to protect temperature sensitive goods such as chilled foods, seafood, dairy products, pharmaceuticals and medical supplies during transport. It helps maintain a controlled internal temperature so products remain safe, fresh and compliant throughout the delivery process.

How does refrigerated packaging maintain temperature?

These systems use a combination of insulation and coolants. Insulated liners, polystyrene boxes or specialised materials slow down heat transfer, while gel packs or water based ice packs provide active cooling. Together, they create a stable environment that protects goods from external temperature changes.

What types of refrigerated packaging does Hydropac offer?

Hydropac supplies a wide range of solutions across its FreshPac and PharmaPac ranges, including insulated liners, recyclable materials, polystyrene containers, gel ice packs, water based ice packs and specialised chilled packaging systems. Each option is designed to support consistent thermal performance.

Is refrigerated packaging suitable for both food and pharmaceutical shipments?

Yes. Hydropac offers tailored packaging for both sectors. FreshPac is designed for food and drink applications, while PharmaPac solutions support medical, healthcare and pharmaceutical products requiring controlled temperatures and validated cooling performance.

How do I choose the right refrigerated packaging for my shipment?

The best choice depends on the type of product, its required temperature range, journey duration and expected handling conditions. Hydropac’s wide portfolio of coolants and insulated packaging makes it easy to build a solution that matches your needs and protects your goods throughout transit.