Trusted by leading companies

Pharmaceutical cold chain solutions

- Certified temperature compliance

- Recyclable, sustainable design

- Proven pharmaceutical performance

Reliable Temperature Control for the Pharmaceutical Industry

Pharmaceutical cold chain solutions are essential for ensuring the safety, stability and effectiveness of temperature-sensitive medicines, vaccines and biologics. These products must be stored and transported under tightly controlled temperature ranges to comply with strict regulatory standards and maintain patient safety.

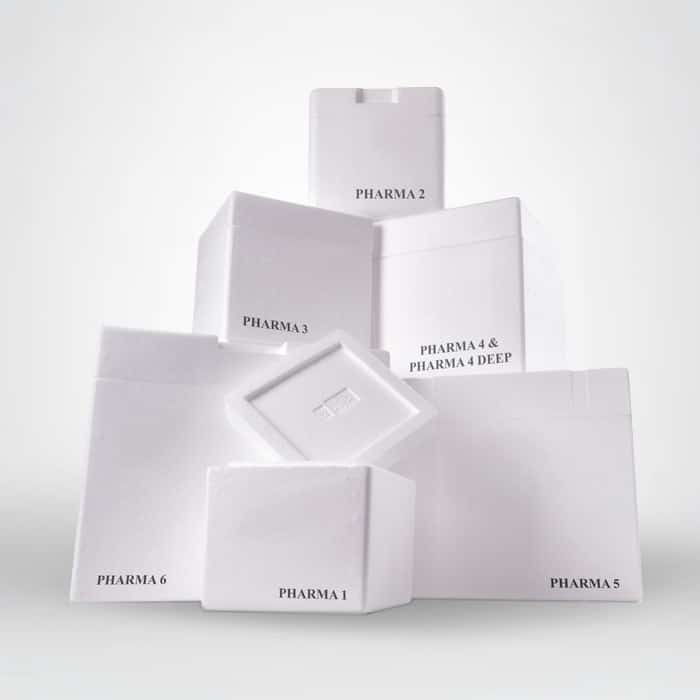

At Hydropac, we design and manufacture specialised packaging systems that protect pharmaceutical goods throughout the supply chain. Our PharmaPac range, including high-performance gel ice packs and polystyrene boxes, provides consistent insulation and temperature regulation. Each solution is developed to meet the highest standards of quality, hygiene and sustainability, supporting pharmaceutical logistics across the UK and beyond.

Discover Pharmaceutical cold chain solutions

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Advanced Cold Chain Systems for Safe Pharmaceutical Transport

Maintaining the integrity of pharmaceuticals during transit requires precision, consistency and compliance with stringent standards. Hydropac’s pharmaceutical cold chain solutions are engineered to safeguard temperature-sensitive products throughout storage and distribution, ensuring they remain within the correct temperature range from production to patient delivery.

Precision in Temperature Management

Pharmaceutical goods such as vaccines, insulin and biological materials are highly sensitive to even slight temperature deviations. To prevent degradation or loss of efficacy, Hydropac offers packaging systems that combine thermal stability with durability. Our PharmaPac gel ice packs and insulated polystyrene boxes are rigorously tested to deliver reliable thermal performance, making them ideal for both chilled and frozen applications.

Sustainable Innovation in Cold Chain Packaging

As the pharmaceutical industry moves toward more sustainable operations, Hydropac continues to develop environmentally responsible cold chain solutions. We focus on recyclable and reusable packaging materials that reduce waste while maintaining product protection. The use of water-based refrigerants and eco-friendly insulation materials reflects our commitment to sustainability without compromising performance.

Designed for Compliance and Confidence

Every aspect of Hydropac’s pharmaceutical packaging adheres to Good Distribution Practice (GDP) and EU regulatory standards for temperature-controlled transport. By integrating innovative sealing technology and precision manufacturing, we help our partners maintain compliance and quality assurance throughout the entire supply chain.

Benefits of Hydropac’s Pharmaceutical Cold Chain Solutions

- Consistent temperature control for chilled, frozen and ambient pharmaceuticals

- Sustainable materials that support corporate environmental goals

- Lightweight yet robust packaging to reduce transport costs

- Proven reliability in both short and long-distance deliveries

- Customisable systems tailored to specific pharmaceutical applications

Hydropac’s expertise ensures that pharmaceutical distributors and healthcare providers can transport sensitive products safely, efficiently and with full confidence in temperature integrity.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about Pharmaceutical Cold Chain Solutions

What are pharmaceutical cold chain solutions?

Pharmaceutical cold chain solutions are systems designed to maintain controlled temperatures for sensitive products such as vaccines, biologics and medicines during transport and storage. They help prevent temperature excursions that could compromise product safety or effectiveness.

Why is temperature control critical in pharmaceutical logistics?

Medicines and vaccines often require strict temperature regulation, typically between 2°C and 8°C, to remain stable and effective. A single temperature breach can reduce potency or render a product unusable, which is why consistent monitoring and reliable packaging are essential.

How do Hydropac’s solutions ensure regulatory compliance?

Hydropac’s cold chain packaging meets Good Distribution Practice (GDP) and relevant EU and UK pharmaceutical transport standards. Every product is manufactured to precise specifications and tested to perform under real-world logistics conditions, ensuring compliance with healthcare regulations.

Are Hydropac’s pharmaceutical packaging products sustainable?

Yes. Hydropac designs cold chain systems with sustainability in mind, using recyclable materials and energy-efficient production methods. Our water-based gel packs and reusable polystyrene boxes help reduce waste and support a more environmentally responsible pharmaceutical supply chain.

Can Hydropac’s cold chain packaging be tailored to specific needs?

Absolutely. Hydropac offers bespoke packaging solutions for a wide range of pharmaceutical applications, from small clinical trial samples to large-scale vaccine distributions. Each system can be customised for temperature range, duration and logistical requirements to ensure optimal protection and performance.