Trusted by leading companies

Pharma cold chain logistics

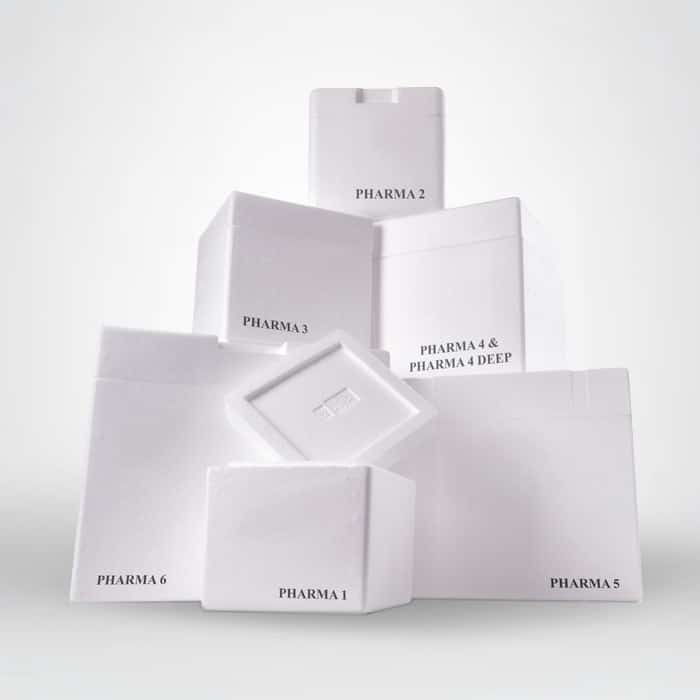

- Precision Engineered Pharmaceutical Packaging

- Consistent, High Quality Coolants

- Compliance Ready Cold Chain Solutions

Safeguarding Medicines with Precision and Control

Pharma cold chain logistics plays a vital role in protecting temperature sensitive medicines, vaccines and biological products from the moment they leave the manufacturer to the time they reach patients. As global healthcare demands continue to rise, so does the need for reliable, compliant and expertly engineered packaging that maintains strict temperature ranges throughout transport. Hydropac supports this mission with specialised PharmaPac systems designed to safeguard pharmaceutical products during storage and distribution. Through precision engineered coolants, insulated containers and validated performance, pharma cold chain logistics ensures product integrity, patient safety and full compliance across every stage of the supply chain.

Discover Pharma cold chain logistics

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Delivering Confidence Across Every Stage of the Pharma Cold Chain

Maintaining temperature stability is one of the greatest challenges in pharmaceutical logistics. Every product, from routine vaccines to complex biologics and advanced therapies, must remain within a precise temperature range to preserve its potency. This requires more than refrigerated transport alone. It demands expertly designed packaging, validated coolants, accurate monitoring and seamless coordination across the supply chain. Hydropac supports this entire journey with specialised solutions that help pharmaceutical businesses stay compliant, efficient and fully in control.

The Critical Role of Temperature Accuracy

Medicines are highly sensitive to fluctuations. Even short exposure to incorrect temperatures can compromise quality or trigger costly product loss. This is why strict temperature control is a cornerstone of pharmaceutical distribution. Within this environment, PharmaPac packaging solutions provide a trusted foundation for maintaining temperatures in refrigerated, frozen or deep frozen conditions. Their predictable cooling behaviour ensures consistency during transit and storage, offering peace of mind for organisations handling sensitive healthcare products.

What Makes the Pharma Cold Chain Unique

Pharmaceutical supply chains must balance scientific requirements, regulatory expectations and operational practicality. Unlike other cold chain sectors, the risks are far greater because product failures can affect patient outcomes. Key characteristics of this environment include:

- Tight temperature bands for vaccines, insulin, biologics and clinical trial materials

- Regulatory oversight from authorities such as the European Medicines Agency and the Food and Drug Administration

- The use of specialised temperature controlled packaging, including gel packs, water based ice packs and insulated containers

- The need for validated, repeatable performance in real world transport conditions

- Increasing reliance on data loggers, temperature sensors and other digital monitoring tools

Hydropac’s expertise in manufacturing high quality coolants and insulated solutions helps ensure that these requirements are met without unnecessary complexity or excessive operational strain.

Packaging as a Foundation for Compliance

Even the most sophisticated temperature controlled vehicle cannot guarantee product integrity without the correct packaging. PharmaPac systems combine reliable insulation with performance tested coolants to create a controlled internal environment. Polystyrene boxes, recyclable insulated liners and carefully engineered gel or water based packs work together to maintain stability throughout each stage of transit. This passive protection is essential for routes involving handovers, warehouse dwell times or door openings where internal temperatures can quickly change.

Supporting Innovation in the Pharmaceutical Supply Chain

As therapies grow more advanced, the cold chain must evolve to support new temperature ranges and handling requirements. Many modern medicines, including next generation biologics and cellular materials, require more stringent control conditions. Hydropac’s commitment to precision manufacturing and sustainable materials helps pharmaceutical companies meet these expectations while improving efficiency. With solutions designed to meet complex temperature needs, pharma cold chain logistics continues to advance the safe delivery of life changing treatments.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's About Pharma Cold Chain Logistics

Why is temperature control so important in pharmaceutical logistics?

Most medicines lose stability when exposed to incorrect temperatures. Even a short deviation can reduce potency or render a product unusable. Temperature control ensures that vaccines, biologics and other sensitive medicines remain safe and effective throughout transport and storage.

What packaging is commonly used in the pharma cold chain?

Pharmaceutical shipments rely on validated insulated containers, polystyrene boxes, gel ice packs, water based ice packs and specialised PharmaPac systems. These solutions work together to maintain a controlled internal environment, even during variable external conditions.

How do temperature monitoring devices support compliance?

Data loggers and temperature sensors provide a continuous record of conditions inside a shipment. This information helps companies verify compliance with regulatory standards and identify potential risks or temperature excursions.

What temperatures are typically required for pharmaceutical products?

The most common ranges include refrigerated conditions between 2 and 8 degrees Celsius, frozen conditions below minus 15 degrees and deep frozen environments for certain biological materials. Each product has its own validated range based on scientific stability data.

How does Hydropac support pharmaceutical cold chain operations?

Hydropac provides specialised PharmaPac packaging, high performance gel and water based ice packs and precision engineered insulated systems that safeguard medicines during every stage of transport. Their consistent manufacturing methods help ensure reliable thermal performance and repeatable conditioning for compliant, secure pharmaceutical logistics.