Trusted by leading companies

Perishable goods shipping

- Expert Temperature Control

- Sustainable Innovation

- Trusted UK Manufacturing

Precision Cooling for Perishable Goods

When it comes to transporting temperature-sensitive items, perishable goods shipping is the cornerstone of quality, safety and reliability. Whether dealing with fresh produce, dairy products or life-saving pharmaceuticals, maintaining the correct temperature throughout the journey is essential to prevent spoilage and preserve integrity.

At Hydropac, we specialise in temperature-controlled packaging that keeps products at their optimal condition from departure to delivery. Our innovative ranges including FreshPac for food, PharmaPac for pharmaceuticals and Ice Packs by Hydropac for chilled and frozen applications combine advanced insulation, sustainable materials and precise engineering to support every stage of the cold chain.

Discover Perishable goods shipping

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Ensuring Quality and Safety in Every Shipment

Successful perishable goods shipping depends on maintaining the correct temperature and humidity throughout the entire supply chain. Even small fluctuations can compromise food quality or reduce the effectiveness of sensitive medicines. That is why the foundation of every shipment lies in reliable, validated packaging.

At Hydropac, we provide advanced temperature-controlled packaging solutions that meet the highest standards for performance and sustainability. Our packaging is designed to protect perishable items from temperature shifts, contamination and handling stress while offering environmentally responsible options that reduce waste.

Intelligent Packaging for Diverse Applications

Every industry faces unique challenges when transporting perishable goods. Hydropac’s product families have been engineered to meet these needs:

- FreshPac – Designed for the food sector, these systems ensure freshness and compliance with hygiene standards. Sub-brands such as EnviroCool, RecycleAir and ReflectiveAir deliver strong insulation and recyclable materials for chilled and frozen foods. Explore more about these systems on the FreshPac page.

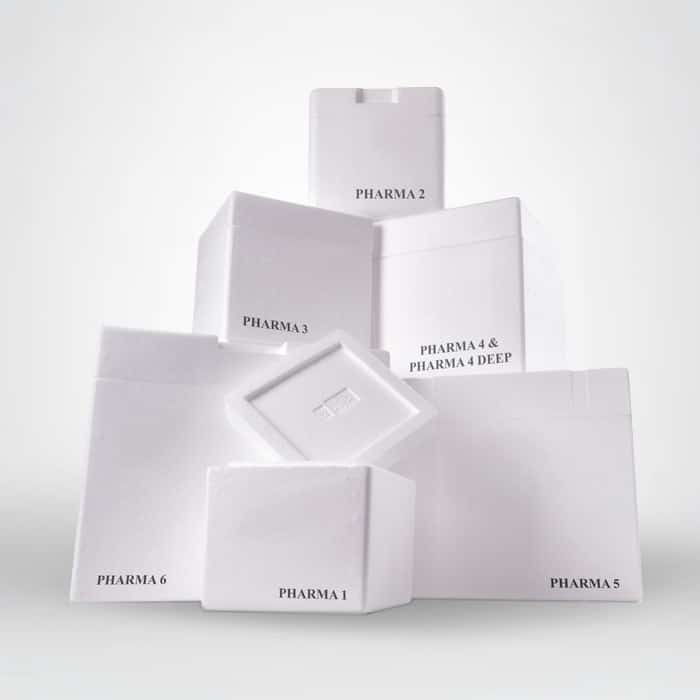

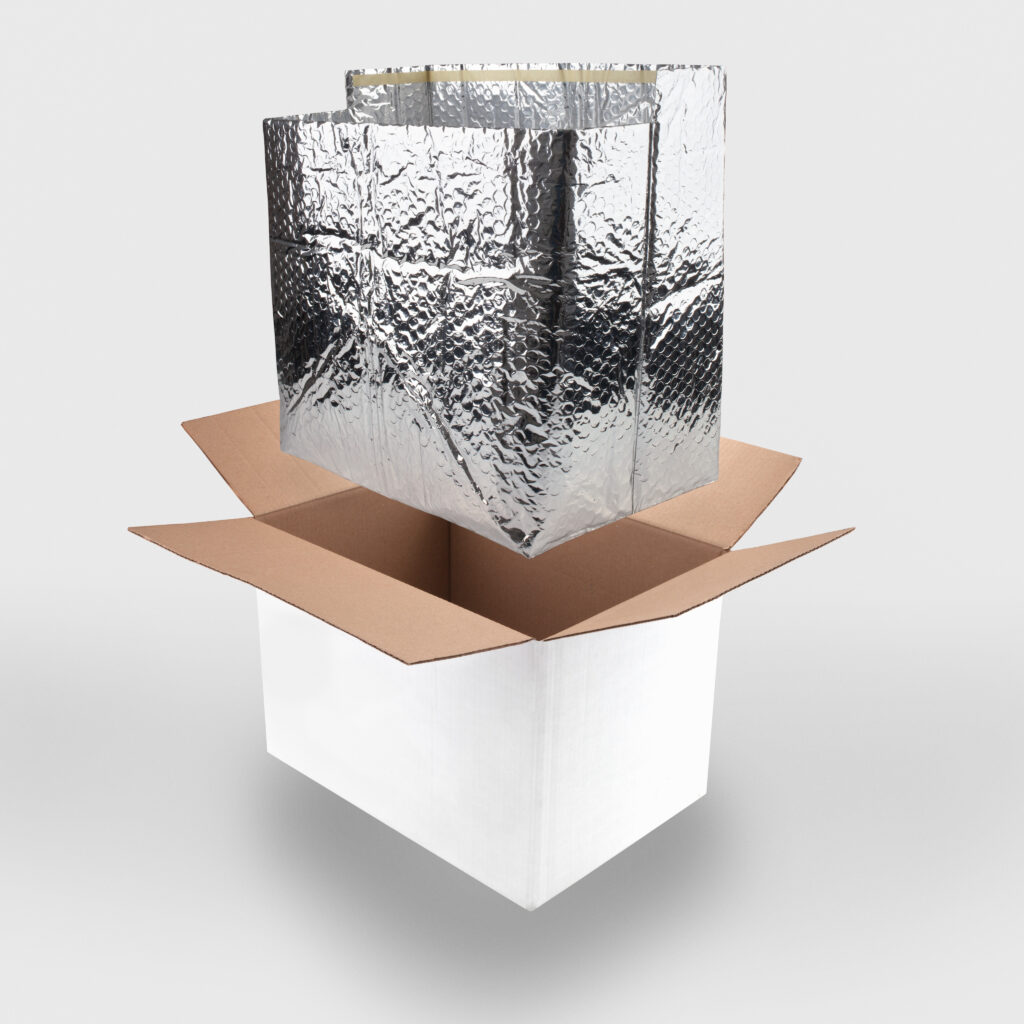

- PharmaPac – Created for pharmaceutical and healthcare applications, these solutions provide temperature consistency for vaccines, medicines and diagnostic materials. Gel ice packs and polystyrene boxes help maintain integrity during long-distance transport. Learn more through PharmaPac.

- Ice Packs by Hydropac – A complete range of water-based, gel-based and hard-shell ice packs for use in chilled, frozen or ambient-controlled environments. All packs are produced using our unique seal through water technology, ensuring hygienic and leak-free performance. View our range on the Ice Packs page.

The Science Behind Temperature Control

Temperature control is not simply a matter of cooling. It involves managing airflow, insulation and phase-change materials to achieve stability throughout transit. Our experts continuously test and refine our products to ensure they maintain precise thermal performance, even under extreme conditions.

- Validated performance for up to 96 hours of stable temperature control

- Recyclable and eco-friendly materials supporting sustainable logistics

- Leak-proof sealing technology for superior hygiene and safety

- Flexible design for food, pharmaceutical and industrial applications

Supporting a Sustainable Cold Chain

As sustainability becomes a global priority, Hydropac remains committed to eco-conscious innovation. By combining recyclable insulation with efficient design, we reduce waste while maintaining the reliability needed for critical cold chain operations. Our products empower businesses to transport perishable goods safely, responsibly and with confidence in every delivery.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about Perishable Goods Shipping

What does perishable goods shipping mean?

Perishable goods shipping refers to the transportation of products that can spoil, decay or lose quality if they are not kept within a specific temperature range. This includes food items such as seafood, dairy products and fresh produce, as well as temperature-sensitive pharmaceuticals. Effective packaging and reliable cold chain management are essential to maintain safety and quality throughout the journey.

How does Hydropac help protect perishable goods during transport?

Hydropac provides advanced temperature-controlled packaging solutions that maintain stable internal conditions from start to finish. Our ranges: FreshPac, PharmaPac and Ice Packs by Hydropac, use high-performance insulation, sustainable materials and precise cooling technologies to prevent spoilage and temperature fluctuations during shipping.

What is seal through water technology and why is it important?

Seal through water technology is a unique Hydropac innovation that ensures every gel or water-based ice pack is completely leak-proof and hygienic. This method allows packs to be sealed securely, even through liquid, reducing contamination risks and ensuring consistent cooling performance.

Are Hydropac products suitable for international perishable goods shipping?

Yes. Hydropac products are designed and tested to perform reliably across different shipping environments, including air freight, road transport and sea freight. Our validated systems can maintain temperature stability for extended periods, making them ideal for global distribution of perishable goods.

How do sustainable materials improve perishable shipping?

Sustainable materials, such as recyclable insulation and eco-friendly liners, help reduce waste and environmental impact without compromising performance. Hydropac’s RecycleAir and ReflectiveAir systems offer strong insulation properties while supporting companies in meeting sustainability and regulatory goals for responsible packaging.