Trusted by leading companies

Insulated pharma shipping

- Precision Temperature Protection

- Certified for Pharma Compliance

- Sustainable, Custom Solutions

Trusted Cold Chain Protection for Life-Saving Pharmaceuticals

When it comes to the safe transport of temperature-sensitive medicines and biological materials, insulated pharma shipping plays a critical role. At Hydropac, we specialise in creating reliable, high-performance packaging solutions designed to maintain stable temperatures throughout the cold chain. Our PharmaPac range includes gel ice packs, EPS containers, and purpose-built insulated boxes that protect pharmaceutical products against temperature fluctuations and transit delays. With decades of expertise in thermal packaging, we support pharmaceutical companies, pharmacies, labs, and healthcare providers in delivering life-saving treatments safely and compliantly. Hydropac ensures every shipment arrives in optimal condition, without compromise.

Discover Insulated pharma shipping

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

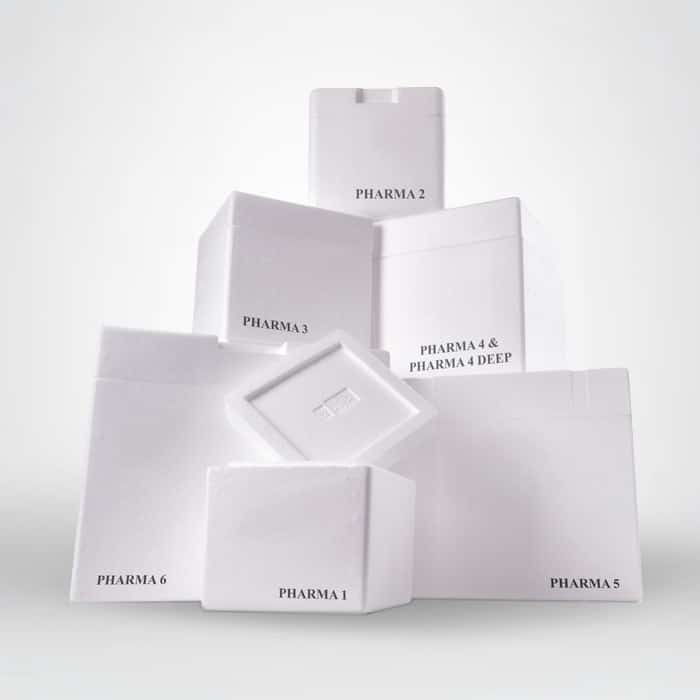

Purpose-Built Protection for Every Pharma Product

In the pharmaceutical world, there’s no room for error. Temperature-sensitive products like vaccines, diagnostic reagents, prescription drugs, and biological samples demand more than just basic insulation. They need smart, high-performance solutions. That’s where Hydropac’s PharmaPac range steps in.

With expertly designed insulated packaging systems, we help pharmaceutical manufacturers, hospitals, laboratories, and logistics providers ensure temperature integrity, regulatory compliance, and supply chain efficiency.

Why PharmaPac Stands Out

At Hydropac, we don’t believe in one-size-fits-all. Instead, we engineer solutions to fit real-world cold chain challenges. Our PharmaPac line is a blend of science, sustainability, and smart engineering:

- Advanced Thermal Packaging

Using EPS foam, polystyrene, and reflective materials, our packaging shields pharma products from temperature extremes, even during long-haul transport. - Precision Gel Ice Packs

Available in a range of sizes and formats, including water-based and gel-filled, our packs are manufactured using our exclusive seal through water technology. This ensures both hygiene and performance. - ISTAs and Regulatory Standards

Every product is tested to meet stringent industry benchmarks such as ISO 9001, EcoVadis, and ISTA. This gives our partners confidence in both performance and compliance. - Temperature Ranges Covered

Whether it’s refrigerated (2–8°C), ambient (15–25°C), or frozen (below -20°C), our solutions are tailored to meet your specific shipping profile. - Sustainability at the Core

Recyclable, reusable, and biodegradable options are available to help pharma clients meet environmental targets without compromising on reliability.

Tailored Solutions for a Changing Industry

Pharmaceutical shipping isn’t just about keeping things cold. It’s about:

- Avoiding temperature excursions during international transit

- Ensuring patient safety through consistent product quality

- Reducing packaging waste in alignment with B Corp and circular economy principles

- Staying compliant with UK and international regulations

At Hydropac, our local team of packaging experts works closely with clients to design bespoke thermal solutions for even the most demanding pharmaceutical applications. From insulated shipping boxes to sustainable cold chain envelopes, we cover every link of the cold chain. Reliably, hygienically, and with innovation built into every product.

Whether you’re shipping blood samples to a lab or life-saving medications overseas, Hydropac ensures your cargo remains protected at every stage of the journey.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about insulated pharma shipping

What is insulated pharma shipping and why is it important?

Insulated pharma shipping refers to the use of specialised packaging designed to maintain a controlled temperature range during the transport of pharmaceuticals. It ensures that temperature-sensitive medicines, vaccines, and biological samples remain effective and safe from the moment they leave the facility to the point of use. Without proper insulation, products risk exposure to temperature fluctuations, leading to degradation or loss of efficacy.

What products does Hydropac offer for pharmaceutical shipping?

Hydropac’s PharmaPac range includes a variety of high-performance solutions such as:

- Gel ice packs and water-based ice packs

- EPS foam insulated boxes and polystyrene containers

- Cold chain mailing envelopes and thermal protection liners

- Sustainable packaging options including recyclable and biodegradable materials

All products are designed to meet industry standards and support various temperature profiles including chilled, ambient, and frozen.

How does Hydropac ensure compliance with pharmaceutical shipping regulations?

Hydropac conducts rigorous in-house and third-party testing, including ISTA and laboratory performance evaluations. Our packaging solutions are developed in line with regulatory expectations from bodies such as the MHRA and other global authorities. We also hold certifications like ISO 9001 and ISO 45001 to guarantee consistent quality and safety.

Are your insulated pharma shipping solutions sustainable?

Yes. Sustainability is a core focus of our packaging design. We offer recyclable EPS, biodegradable materials, and reusable options to support clients working toward their environmental and B Corp goals. We also minimise packaging waste and promote circular economy practices across our product lifecycle.

Can I get custom packaging tailored to my pharmaceutical product?

Absolutely. Hydropac specialises in bespoke insulated solutions. Whether you need branding, specific temperature durations, unique sizes, or advanced insulation materials like fleece or aerogel, our team can craft a solution that fits your exact requirements. There are no tooling charges for custom designs, and our experts will guide you through the entire process.