Trusted by leading companies

Insulated medical packaging

- Pharmaceutical-grade protection

- Sustainable temperature control

- Clinically tested reliability

What Is Insulated Medical Packaging?

Insulated medical packaging is essential for protecting temperature-sensitive pharmaceuticals, biological samples and medical supplies during storage and transport. Designed to maintain strict temperature ranges, it ensures the integrity and safety of products such as vaccines, insulin, and diagnostic specimens.

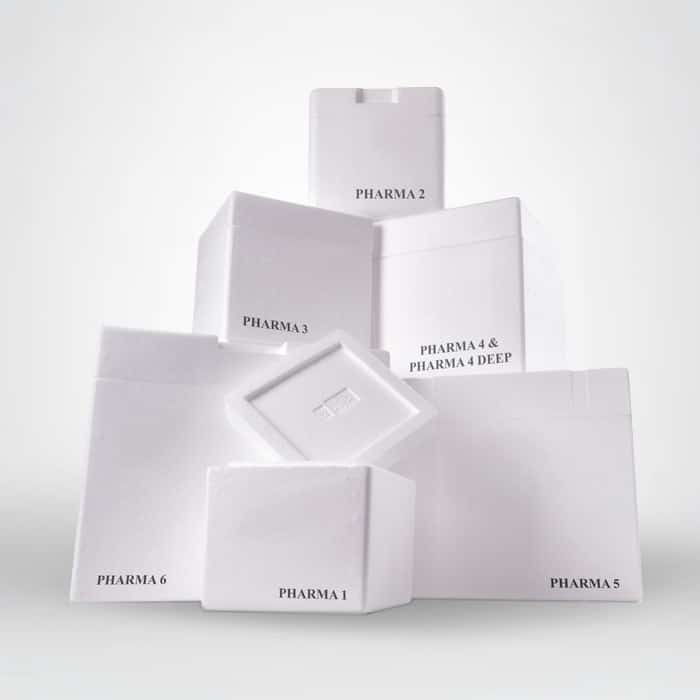

At Hydropac, we develop sustainable, high-performance insulation systems that meet the rigorous demands of the healthcare and life sciences sectors. Our PharmaPac range includes precision-engineered boxes, gel packs and liners that comply with Good Distribution Practice (GDP) and ISO standards. Each solution offers dependable temperature control, secure handling and environmental responsibility for every shipment, from laboratory to patient.

Discover Insulated medical packaging

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Precision and Protection in Every Shipment

The healthcare and pharmaceutical industries rely on absolute consistency when it comes to temperature control. Even the slightest deviation can compromise the efficacy of a medicine or diagnostic sample. Insulated medical packaging provides the controlled environment necessary to ensure that products remain within their defined temperature range throughout transit, whether they are moving between laboratories, hospitals or international destinations.

At Hydropac, we combine scientific expertise with innovative materials to produce packaging that protects both the product and the planet. Our PharmaPac range is specifically designed for the challenges of modern cold chain logistics, providing outstanding thermal performance, durability and sustainability.

The Science Behind Reliable Thermal Control

Hydropac’s insulated systems use a combination of advanced materials and refrigerants to maintain internal stability. These include gel ice packs, insulated box liners, and water-based coolants, all tested under real transport conditions in our dedicated climate chamber. The result is dependable packaging that withstands fluctuations in temperature, vibration and handling stress.

Our packaging solutions are validated to support temperature ranges between -18°C and +10°C, making them ideal for sensitive products such as vaccines, insulin, biologics and medical samples. This versatility allows hospitals, laboratories and pharmaceutical distributors to ship items safely and efficiently while meeting EU GDP guidelines.

Sustainable Materials for a Healthier Future

As environmental standards tighten across the healthcare sector, sustainability has become a defining factor in medical logistics. Hydropac’s approach combines high-performance insulation with recyclable and renewable materials such as wool-based liners and recyclable polyethylene films. These materials deliver robust temperature retention while reducing environmental impact.

Hydropac also offers EcoWool Box Liners, a natural and biodegradable solution that replaces conventional polystyrene boxes. Wool’s natural fibres create an effective insulating layer, while its breathability prevents condensation and bacterial growth, key for sterile environments. You can explore similar options within our sustainable FreshPac range, including Wool Postal Pockets.

Benefits of Hydropac’s Insulated Medical Packaging

- Validated performance: Tested in controlled conditions to guarantee consistent results.

- Regulatory compliance: Meets strict pharmaceutical and healthcare standards.

- Eco-conscious design: Uses recyclable, renewable and biodegradable materials.

- Durable protection: Guards against temperature fluctuations, impact and moisture.

- Customised solutions: Tailored to meet specific medical transport requirements.

Engineered for Confidence and Compliance

Hydropac understands that temperature-controlled logistics are mission-critical. Every PharmaPac product is built to deliver reliable protection during extended shipping times, regardless of season or destination. By pairing innovation with regulatory expertise, Hydropac supports healthcare providers and pharmaceutical partners in maintaining both product integrity and environmental responsibility.

Our insulated medical packaging is more than a layer of protection, it is a scientifically validated system that safeguards life-saving products with precision, compliance and care.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about Insulated Medical Packaging

What is insulated medical packaging used for?

Insulated medical packaging is designed to protect temperature-sensitive pharmaceuticals, biological samples and medical supplies during storage and transit. It ensures that products such as vaccines, insulin and diagnostic kits stay within their safe temperature range, preserving quality and compliance throughout distribution.

How does Hydropac ensure packaging meets medical standards?

All Hydropac products, including those in the PharmaPac range, are rigorously tested under real-world transport conditions. Each design undergoes climate chamber validation to ensure compliance with EU GDP guidelines and ISO quality standards, guaranteeing that temperature-sensitive products remain stable and protected.

Are Hydropac’s medical packaging materials eco-friendly?

Yes. Hydropac is committed to sustainable innovation. Many of our insulated packaging systems use recyclable or biodegradable materials, such as wool-based liners and recyclable polyethylene films. These eco-conscious solutions offer high thermal performance without compromising environmental responsibility.

Can insulated medical packaging be reused?

In many cases, yes. Hydropac’s packaging is built for durability and can be reused multiple times if handled correctly. This approach not only reduces environmental waste but also lowers operational costs for laboratories and pharmaceutical distributors.

What temperature ranges can Hydropac packaging support?

Our insulated medical packaging solutions are validated to maintain critical temperature zones, including frozen (-18°C), chilled (+2°C to +8°C) and ambient (+10°C to +25°C) conditions. This flexibility ensures suitability for a wide variety of products across healthcare, laboratory and pharmaceutical applications.