Trusted by leading companies

Thermal liners for shipping

- High Performance Insulated Packaging

- Consistent, Quality Controlled Coolants

- Reliable Protection for Temperature Sensitive Goods

Reliable Insulation for Temperature Sensitive Shipments

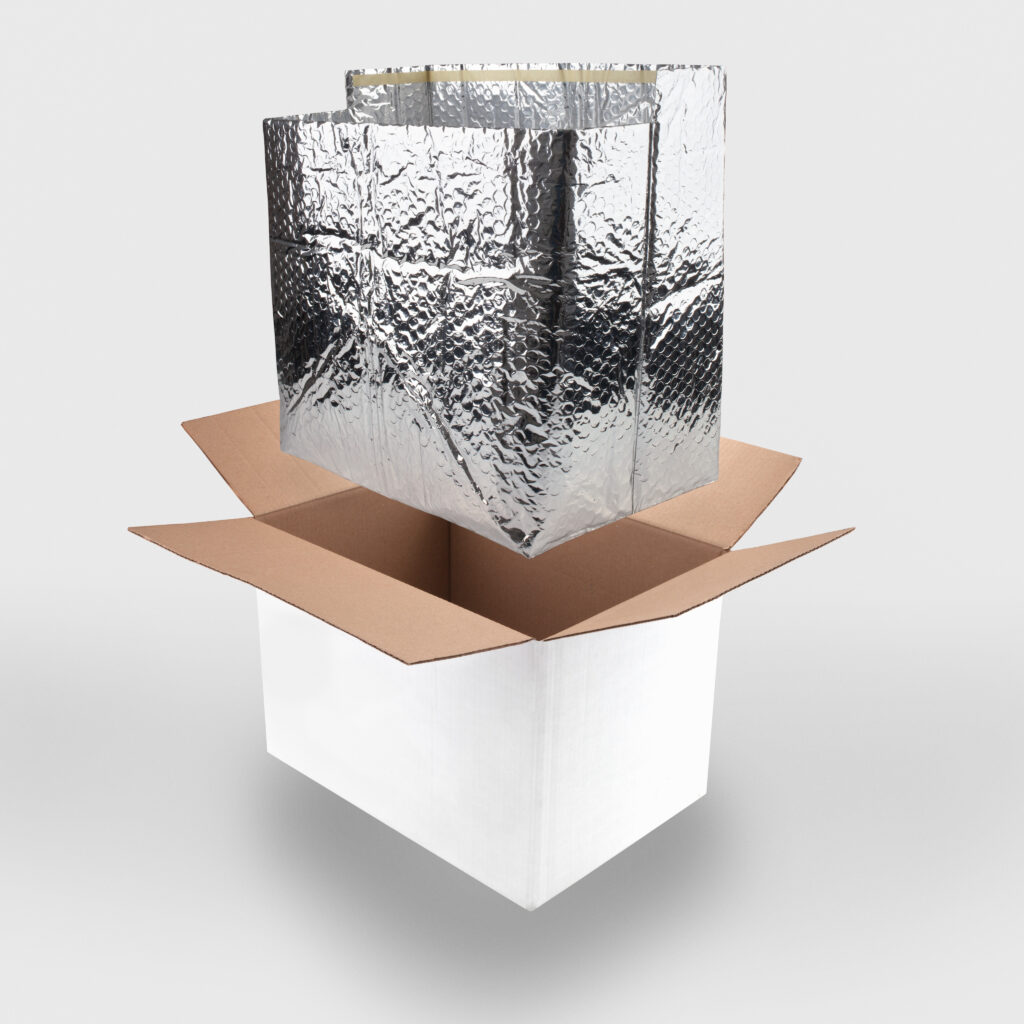

Thermal liners for shipping provide essential protection for products that require stable temperatures during transit. Whether transporting chilled foods, pharmaceuticals or delicate perishables, these liners create a controlled internal environment that reduces heat transfer and shields goods from external conditions. Hydropac supports this need with expertly crafted insulated solutions across its FreshPac and PharmaPac ranges, offering dependable performance for both short haul and long distance distribution. Designed with high quality materials and consistent manufacturing standards, thermal liners for shipping help safeguard temperature sensitive products with confidence and efficiency.

Discover Thermal liners for shipping

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Creating a Stable Thermal Environment in Transit

Thermal liners play a crucial role in protecting temperature sensitive goods during transport. They act as a barrier against heat transfer, helping shipments remain stable even when external conditions fluctuate. For businesses moving chilled foods, pharmaceuticals or other perishable products, reliable insulation can be the difference between a secure delivery and costly spoilage. Hydropac supports this requirement with expertly engineered liners and insulated systems across its FreshPac and PharmaPac families, each designed to maintain product integrity throughout the journey.

How Thermal Liners Protect Temperature Sensitive Products

Thermal liners are designed to minimise the impact of external heat by creating an insulated layer around the shipment. When paired with precision cooled gel packs or water based ice packs from Hydropac, they help maintain consistent temperatures for extended periods. This makes them ideal for a wide range of industries, including food and pharmaceutical sectors where stability and compliance are essential. Hydropac’s insulated solutions, such as EnviroCool and RecycleAir, provide dependable thermal performance while supporting sustainable business practices.

Built for Real World Transport Conditions

Shipments often face variable environments, from warm warehouses to long delivery routes. Thermal liners are engineered to resist these challenges by reducing thermal conductivity and supporting a controlled internal atmosphere. Hydropac’s liners are made using high quality materials and advanced construction techniques that provide strength, flexibility and reliable thermal protection. When combined with accurately conditioned coolants from the Ice Packs by Hydropac range, these liners help maintain temperatures even in demanding distribution conditions.

Enhanced Performance Through Material and Design

The effectiveness of a thermal liner is influenced by its design and the materials used. Hydropac’s FreshPac and PharmaPac solutions incorporate features that support excellent insulation and easy handling, helping teams pack and dispatch temperature sensitive goods with confidence. Key qualities include:

- Lightweight construction that reduces transport costs

- Reflective surfaces that help protect goods from radiant heat

- Strong internal structure that supports consistent insulation

- Compatibility with gel packs, water based coolants and insulated boxes

- Eco friendly options designed to reduce environmental impact

These attributes ensure that Hydropac’s liners deliver predictable thermal performance, even across long distance or multi stage transport routes.

Supporting Safe and Efficient Supply Chains

Thermal liners form a vital part of modern cold chain logistics. As consumer expectations rise and regulations surrounding food and pharmaceutical shipments become more stringent, dependable insulation becomes a necessity rather than an option. Hydropac’s solutions help businesses maintain compliance, protect product quality and streamline operations through packaging that is reliable, reusable and purpose built for temperature sensitive goods.

Whether used inside insulated containers, paired with gel or water based packs or integrated into a wider temperature controlled system, Hydropac’s thermal liners provide robust protection that supports safe and efficient delivery across the supply chain.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's About Thermal Liners for Shipping

What are thermal liners used for in shipping?

Thermal liners are used to protect temperature sensitive products during transit by reducing heat transfer and stabilising the internal environment of a package. They are commonly used for food, pharmaceuticals and other perishable goods that require controlled temperatures.

How do thermal liners help maintain temperature?

Thermal liners create an insulated barrier that slows heat movement from the outside to the inside of the package. When combined with gel packs or water based ice packs from Hydropac, they help maintain consistent temperatures for extended periods, even in changing external conditions.

Are thermal liners suitable for both chilled and frozen goods?

Yes. Thermal liners can support both chilled and frozen applications when paired with the appropriate coolant. Hydropac’s range of Ice Packs provides reliable cooling performance for a variety of temperature requirements.

What makes Hydropac’s thermal liners different?

Hydropac uses high quality materials and precise manufacturing techniques to create liners that offer dependable insulation, durability and ease of use. Solutions such as EnviroCool and RecycleAir provide strong thermal performance while supporting sustainable packaging practices.

Can thermal liners help reduce shipping costs?

Thermal liners are lightweight and flexible, which helps reduce overall shipment weight and transport costs. Their efficient insulation also reduces product loss due to temperature deviations, supporting a more cost effective and reliable cold chain.