Trusted by leading companies

Insulated shipping supplies

- Tailored insulation for every product type

- Sustainably designed for modern logistics

- GDP-compliant, validated performance

Insulated shipping solutions that safeguard performance and compliance

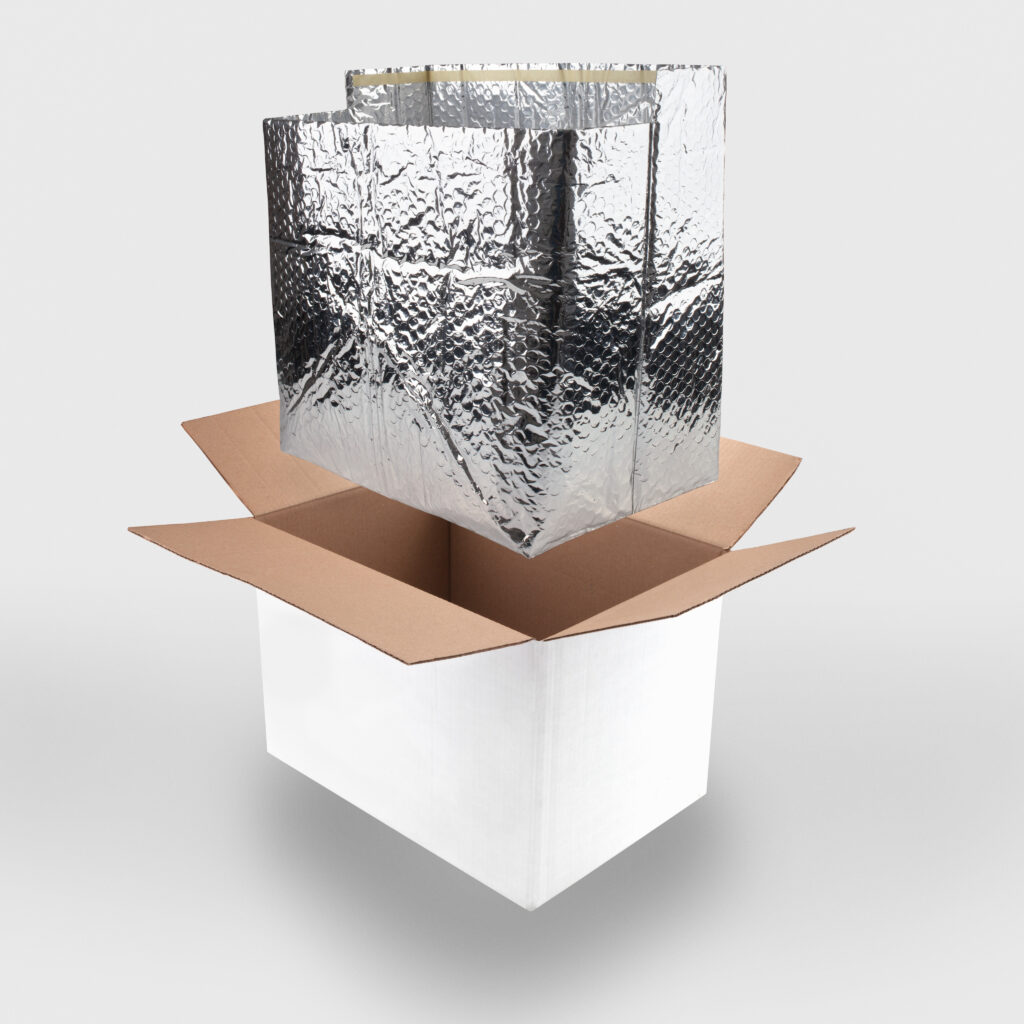

When it comes to transporting temperature-sensitive goods—be it pharmaceuticals, chilled foods or biological samples—insulated shipping supplies play a vital role in ensuring product integrity. At Hydropac, we understand that performance, compliance and sustainability must go hand in hand. Our insulated shipping solutions are designed to protect perishable items throughout the entire cold chain journey, from manufacturing to final delivery. With our FreshPac, PharmaPac and Ice Packs ranges, we offer a tailored approach to insulation—combining recyclable materials, reliable thermal performance, and innovative packaging formats. In this guide, we explore what makes effective insulated shipping supplies and how Hydropac sets the standard for reliable, future-proofed solutions.

Discover Insulated shipping supplies

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Purpose-built protection for sensitive shipments

Insulated shipping supplies are more than just boxes and ice packs—they are essential tools for maintaining the integrity of temperature-sensitive goods in transit. Whether you’re shipping perishable foods or critical pharmaceutical products, the right combination of insulation, coolant, and outer packaging can make all the difference in ensuring product quality upon arrival.

At Hydropac, we take a bespoke approach to thermal protection. By offering a wide array of insulated packaging—from expanded polystyrene (EPS) containers and foil-lined box liners to recyclable cardboard outers—we help businesses across sectors deliver safely and efficiently, every time.

How insulated shipping systems work

Effective insulated shipping solutions are designed to protect contents from temperature fluctuations by reducing heat transfer through conduction, convection, and radiation. Typically, this is achieved by layering high-performance insulation materials (such as EPS or foil-laminated liners) with refrigerants like gel or water-based ice packs.

Hydropac’s packaging systems are engineered to:

- Minimise thermal conductivity through well-sealed insulation

- Extend safe temperature duration for chilled or frozen goods

- Offer lightweight, stackable formats to streamline transport and reduce emissions

Our systems are also compatible with a range of refrigerants and can be tailored to match your payload volume, shipping distance, and storage conditions.

Sustainable materials meet performance

While performance is paramount, sustainability is no longer optional. Hydropac is committed to reducing environmental impact without compromising thermal integrity. That’s why many of our solutions use recyclable outer cartons, LDPE film, and biodegradable insulation components.

We also offer:

- Packaging that aligns with domestic recycling schemes

- Custom-built boxes that minimise material waste and maximise internal space

- Solutions compatible with dry ice or alternative refrigerants for ultra-cold applications

This balance of eco-conscious design and practical usability supports both operational efficiency and your broader sustainability goals.

Supporting compliance across regulated industries

Industries such as healthcare, life sciences, and food logistics face increasingly complex regulatory requirements for cold chain management. Hydropac’s insulated shipping solutions are developed in alignment with Good Distribution Practice (GDP) standards and other international benchmarks, helping customers meet stringent audit and safety protocols.

Each product is tested under realistic thermal conditions and validated for critical time–temperature ranges. For added assurance, our packaging can be paired with temperature loggers and tracking devices to provide real-time data during transit.

By combining technical precision, durable construction, and regulatory readiness, Hydropac delivers insulated shipping supplies that protect both your products and your reputation.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about Insulated shipping supplies

What types of goods require insulated shipping supplies?

Insulated shipping supplies are essential for any product that is sensitive to temperature fluctuations. This includes fresh and frozen foods, dairy, seafood, meats, chocolates, pharmaceuticals (such as vaccines and insulin), biologics, and laboratory samples. These products often have strict temperature maintenance requirements to prevent spoilage, degradation, or loss of efficacy.

What’s the difference between EPS and cardboard-based insulation?

Expanded Polystyrene (EPS) offers excellent thermal insulation and is ideal for long-duration cold chain transport. It’s lightweight, durable, and moisture-resistant. Cardboard-based insulation, on the other hand, often includes thermal liners or foil-backed materials that are more eco-friendly and recyclable. The choice depends on the required temperature range, shipping duration, and sustainability goals.

How long can Hydropac insulated packaging maintain temperature?

The duration depends on several factors, including the type of insulation, the refrigerant used (gel packs, dry ice, etc.), and ambient conditions. For example, our EPS systems paired with gel ice packs can maintain chilled conditions for up to 48–72 hours. We provide performance data and can tailor solutions based on your specific shipping profiles.

Can your insulated shipping boxes be reused?

Yes. Many of our insulated containers are designed for multiple use cycles, particularly those made from durable EPS or with reinforced outer cartons. Reuse depends on maintaining the integrity of the packaging after each journey. We also offer guidance on inspection and reconditioning for extended lifespan.

Do I need temperature monitoring for every shipment?

For highly regulated sectors such as pharmaceuticals or diagnostics, temperature monitoring is often a compliance requirement. Hydropac’s packaging is compatible with most temperature data loggers and can be integrated with your preferred tracking systems. For food shipments or short-haul deliveries, monitoring is optional but strongly recommended to ensure quality assurance and traceability.