Trusted by leading companies

Insulated packaging solutions

- Sustainable cold chain protection

- Precision temperature control

- Custom-engineered packaging

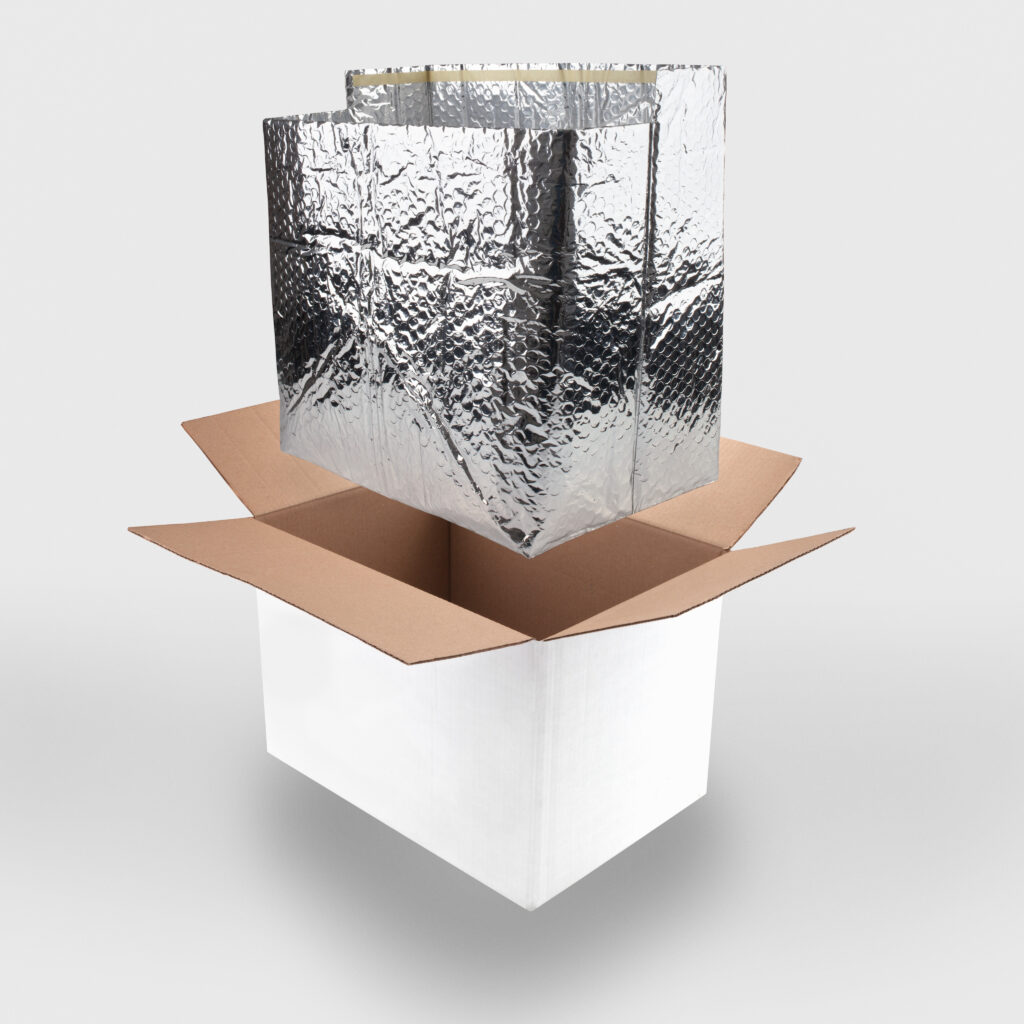

What Are Insulated Packaging Solutions?

Insulated packaging solutions are essential for protecting temperature-sensitive goods during storage and transport. They help maintain the correct temperature range, prevent contamination, and ensure product integrity from dispatch to delivery. Used widely in the food, pharmaceutical and healthcare sectors, they form the backbone of the modern cold chain.

At Hydropac, we specialise in creating high-performance insulated packaging that balances reliability with sustainability. Our expertly engineered systems, including FreshPac, PharmaPac, and Ice Packs by Hydropac, provide precise temperature control and eco-friendly materials. From meal kits to vaccines, Hydropac ensures safe, compliant and environmentally responsible temperature-controlled delivery.

Discover Insulated packaging solutions

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Engineered to Protect, Designed to Perform

When it comes to temperature-sensitive logistics, insulated packaging solutions are not just an option, they are a necessity. They safeguard products from temperature fluctuations, external impact and humidity, ensuring that perishable or delicate goods arrive in perfect condition. Whether it’s fresh food, pharmaceuticals or biological materials, maintaining thermal stability during transit is critical to preserving quality, safety and compliance.

At Hydropac, we bring together innovation, sustainability and precision engineering to deliver packaging that exceeds industry standards. Our solutions are tested under real-life logistics conditions to guarantee durability, performance and environmental responsibility.

Innovation Through Trusted Cold Chain Expertise

Hydropac’s insulated packaging systems are designed for versatility across industries. Our FreshPac range provides dependable protection for food and grocery deliveries, maintaining freshness and flavour with options like EnviroCool, RecycleAir, and ReflectiveAir. For the pharmaceutical and healthcare sectors, the PharmaPac range delivers precision temperature control that meets Good Distribution Practice (GDP) and ISO 9001 standards, ensuring consistent performance during medical transport.

Hydropac’s proprietary seal through water technology ensures each pack remains leak-proof, hygienic and long-lasting. Whether paired with gel packs, ice packs, or insulated box liners, our packaging creates an optimised thermal barrier for both chilled and frozen goods.

Sustainable Materials for a Greener Supply Chain

As the global logistics sector moves toward circular economy principles, Hydropac leads the way with recyclable and biodegradable insulation materials. Our EcoWool Box Liners and RecycleAir systems combine high insulation efficiency with environmental responsibility. Designed to replace traditional polystyrene, these materials are kerbside recyclable and biodegradable, reducing waste without sacrificing performance.

For businesses looking to improve their environmental credentials, Hydropac offers eco-conscious packaging that aligns with Extended Producer Responsibility (EPR) and Packaging and Packaging Waste Regulation (PPWR) standards. You can explore examples of this within our FreshPac Wool Postal Pockets range (see here), an ideal option for sustainable food or pharmaceutical shipments.

Benefits of Hydropac’s Insulated Packaging

- Reliable thermal performance: Proven insulation for chilled and frozen supply chains.

- Eco-friendly design: Recyclable, biodegradable and responsibly sourced materials.

- Durable protection: Withstands vibration, stacking and varied ambient temperatures.

- Custom-built solutions: Tailored to product type, temperature range and logistics route.

- Regulatory compliance: Validated to meet GDP, ISO and food safety standards.

Tested for Performance and Efficiency

Every Hydropac system undergoes rigorous climate chamber testing to ensure optimal thermal performance in real-world delivery conditions. This process simulates environmental stresses such as heat exposure, handling and prolonged transit. The result is packaging that maintains temperature integrity and ensures product safety for extended durations.

By combining science-led testing with sustainable design, Hydropac’s insulated packaging solutions deliver the performance businesses rely on while supporting the planet’s future.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about Insulated Packaging Solutions

What industries use insulated packaging solutions?

Insulated packaging is widely used across industries that handle temperature-sensitive goods, including food, pharmaceuticals, healthcare, and biotechnology. It ensures safe delivery of perishable items such as meat, dairy, seafood, vaccines, and medical samples by maintaining controlled temperatures throughout the cold chain.

What makes Hydropac’s insulated packaging different?

Hydropac combines innovation and sustainability in every design. Our insulated systems are climate-tested, GDP-compliant, and made with eco-friendly materials such as wool liners and recyclable polyethylene films. Each product is engineered to deliver reliable temperature control while minimising environmental impact.

Is insulated packaging environmentally friendly?

Yes, Hydropac’s insulated packaging is developed with sustainability in mind. Our EcoWool Box Liners, RecycleAir, and EnviroCool ranges are made using recyclable and biodegradable materials, providing effective thermal protection without contributing to landfill waste.

Can insulated packaging be customised for specific products?

Absolutely. Hydropac offers fully bespoke solutions to suit different products, volumes and temperature requirements. Whether for frozen, chilled or ambient shipments, our packaging can be tailored in size, thickness and insulation material to match precise logistics needs.

How is the performance of Hydropac’s insulated packaging tested?

All Hydropac packaging solutions undergo climate chamber validation to replicate real transport conditions, including temperature fluctuations and long-duration storage. This ensures that our products consistently meet ISO and food safety standards, providing guaranteed reliability and compliance in every shipment.