Trusted by leading companies

Insulated food packaging

- Sustainable temperature control

- Rigorously climate-tested

- Custom food packaging

What Is Insulated Food Packaging?

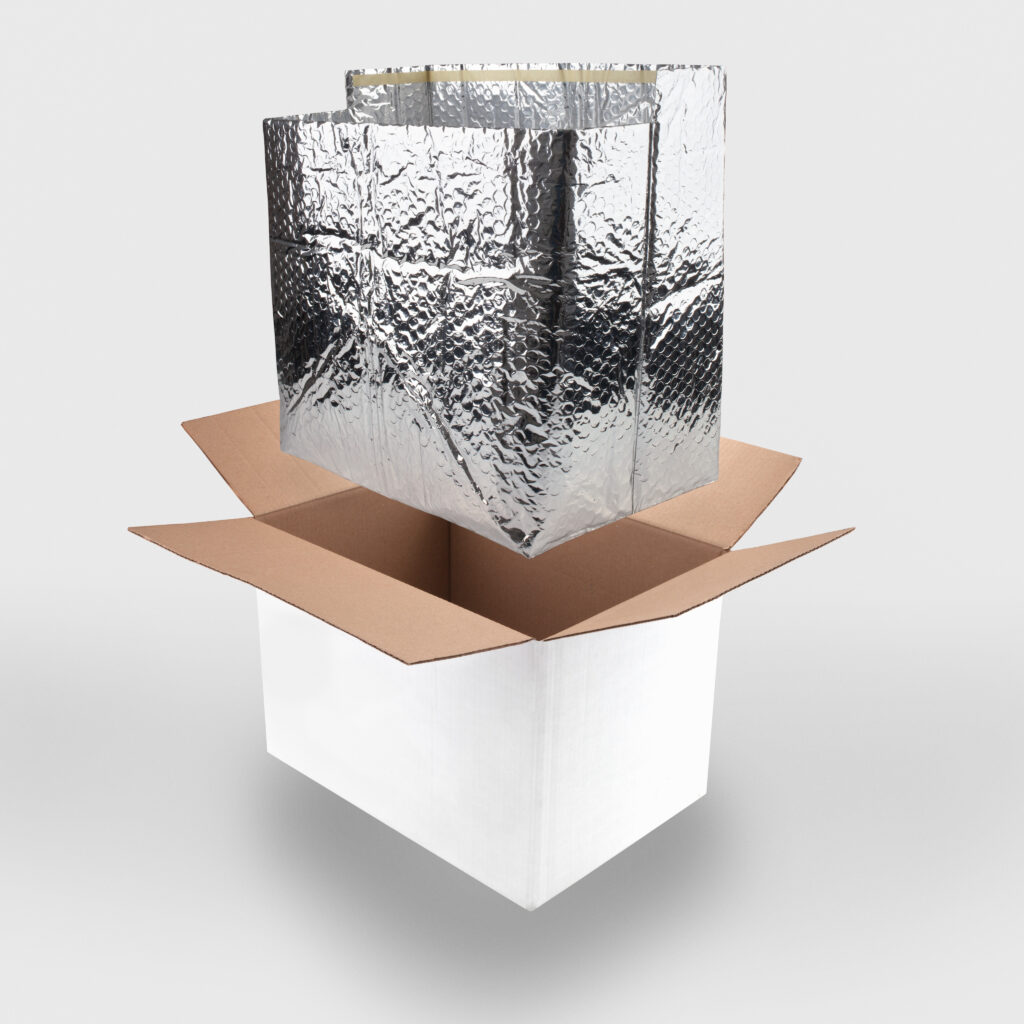

Insulated food packaging is essential for maintaining the correct temperature of perishable goods throughout storage, transport and delivery. It helps protect products such as fresh produce, dairy, meat and ready-to-eat meals from temperature fluctuations that can compromise food quality and safety.

At Hydropac, we specialise in advanced, sustainable insulation systems that keep food items in perfect condition during transit. Our FreshPac range offers innovative solutions like EnviroCool, RecycleAir and ReflectiveAir, designed to deliver exceptional thermal performance while supporting eco-friendly and recyclable practices. Whether for meal kits, grocery delivery or restaurant catering, Hydropac ensures freshness and reliability from packaging to plate.

Discover Insulated food packaging

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Keeping Food Fresh from Packing to Plate

In a world of fast deliveries and rising sustainability demands, insulated food packaging plays a vital role in preserving freshness and preventing waste. Designed to maintain precise temperatures during transport, it ensures food arrives in perfect condition, even after long journeys or fluctuating ambient conditions.

At Hydropac, our insulated packaging systems combine technical precision with sustainable materials. From flexible pouches to rigid boxes, every solution undergoes extensive testing to guarantee food safety, energy efficiency and compliance with food-handling regulations.

Why Insulated Packaging Matters

Whether you’re delivering chilled groceries, gourmet meal kits or takeaway dishes, temperature consistency is key. Insulated packaging prevents heat transfer through its multi-layer construction, reducing the risk of spoilage and maintaining food quality from dispatch to delivery.

Hydropac’s FreshPac range has been engineered for performance and practicality. Using innovative materials and eco-conscious design, these systems support a reliable cold chain while helping businesses reduce environmental impact.

Key benefits include:

- Thermal reliability: Maintains optimal temperature for chilled or frozen goods during extended deliveries.

- Durability: Resistant to crushing, leaks and condensation.

- Sustainability: Crafted using recyclable or biodegradable materials such as RecycleAir and EnviroCool.

- Flexibility: Suitable for both hot and cold applications, from restaurant catering to home deliveries.

- Customisation: Available in a range of sizes and specifications for every type of perishable item.

Sustainable Packaging for a Changing Market

With new UK and EU regulations such as Extended Producer Responsibility (EPR) and Packaging and Packaging Waste Regulation (PPWR), businesses are expected to use recyclable, responsibly sourced materials. Hydropac is proud to lead this change with packaging that aligns performance with sustainability.

Products like our Wool Postal Pockets (learn more here) offer natural, renewable insulation that’s ideal for temperature-sensitive food deliveries. Unlike polystyrene, these wool-based liners are fully recyclable and compostable, helping reduce waste without compromising quality.

Designed for Real-World Logistics

Hydropac’s insulated solutions are rigorously tested under real transport conditions, ensuring each product can withstand the stress of constant movement, vibration and variable temperatures. Whether stacked in bulk shipments or delivered in compact meal kits, the packaging maintains consistent insulation performance.

Our focus on climate testing and quality validation means Hydropac packaging meets the highest standards of food safety and thermal efficiency. From ice packs and gel coolants to insulated boxes and liners, every component is designed to work as part of a complete temperature-controlled system.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about Insulated Food Packaging

What materials are used in insulated food packaging?

Insulated food packaging is typically made from materials that reduce heat transfer, such as foil-lined films, recycled paper fibres, or wool-based insulation. Hydropac’s FreshPac range uses high-performance, recyclable materials like RecycleAir, ReflectiveAir, and natural wool liners to ensure effective temperature control while supporting sustainability goals.

How does insulated packaging maintain temperature during delivery?

It works by trapping air within layers of thermal material to slow down heat exchange between the product and its surroundings. When combined with ice packs or gel coolants, this creates a stable microclimate that protects perishable goods during long or multi-stop deliveries.

Is insulated food packaging recyclable or reusable?

Yes, many of Hydropac’s insulated packaging systems are recyclable or made from renewable materials. Options like EnviroCool and Wool Postal Pockets are designed with sustainability in mind, allowing customers to reuse or recycle components after use to minimise waste.

What types of food benefit most from insulated packaging?

Insulated food packaging is essential for products that require temperature stability, such as dairy, meat, seafood, meal kits and ready-to-eat dishes. It is also suitable for hot food delivery, ensuring warmth and freshness are maintained from kitchen to customer.

How is Hydropac’s insulated packaging tested for performance?

All Hydropac products undergo rigorous climate chamber testing to replicate real-world conditions, including temperature fluctuations and transit stress. This ensures every system performs reliably under pressure, meeting food safety and performance standards for modern cold chain logistics.