Trusted by leading companies

High-performance cooling insulation

- Precision Temperature Control

- Eco-Friendly Materials

- Proven Cold Chain

Reliable insulation for critical cold chain protection

From pharmaceutical deliveries to gourmet meal kits, high-performance cooling insulation is the unsung hero behind safe, temperature-controlled transit. At Hydropac, we understand that keeping perishable goods fresh is not a luxury; it is a necessity. Whether transporting life-saving medication or artisan cheese, our advanced insulation materials maintain critical temperatures with precision. Through innovative technologies and brand-specific solutions, such as FreshPac’s food-focused EnviroCool and RecycleAir, or PharmaPac’s rigorously tested gel packs and polystyrene containers, we offer cooling insulation that is both high-performing and environmentally mindful. Reliable, hygienic and expertly engineered, our insulation solutions give businesses the confidence to deliver quality every time.

Discover High-performance cooling insulation

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Precision Cooling Starts with Smarter Insulation

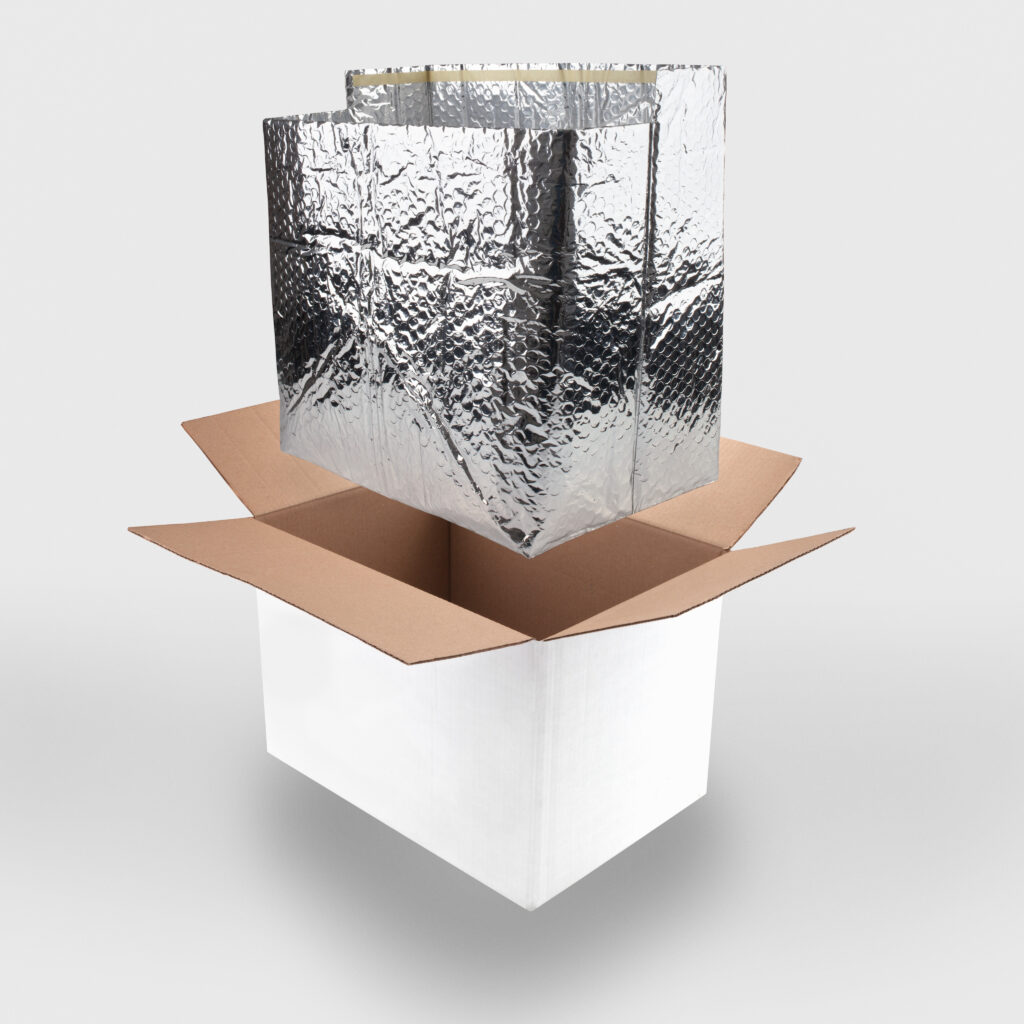

At the core of every reliable cold chain is insulation that does more than just slow down temperature changes. High-performance cooling insulation from Hydropac is developed to deliver stable thermal protection, regardless of external conditions or delivery duration. It is about preserving freshness, protecting sensitive items, and doing so with sustainability and safety in mind.

Built for Performance in Food and Pharma

Hydropac’s cooling insulation systems are purpose-built to meet the demands of different industries, from chilled food to critical pharmaceutical goods.

- FreshPac: This food-focused range includes EnviroCool, a kerbside recyclable solution using paper-based liners. RecycleAir is a lightweight insulation option filled with 100% recycled PET fibres, offering solid thermal performance with a lower carbon footprint. ReflectiveAir uses foil-lined bubble layers to reflect heat and maintain a chilled environment for shorter transit windows.

- PharmaPac: Specifically designed for pharmaceutical use, this range includes gel-based ice packs and EPS containers that offer excellent thermal insulation. These products support controlled room temperature and refrigerated transport, which are vital for medicines, vaccines and diagnostics.

- Ice Packs by Hydropac: Our in-house manufactured ice packs are made with our seal through water technology. This process delivers high levels of hygiene and leak prevention. The range includes flexible gel packs, water-based solutions and hard shell options to suit different payload types and temperature requirements.

Why High-Performance Cooling Insulation Matters

Using advanced insulation is not just about keeping products cold. It also adds value to your logistics and enhances product safety.

- Consistent Cold Chain: Our insulation solutions help maintain target temperatures for up to 48 hours or more when paired with the correct ice pack configuration.

- Tested and Verified: All products undergo in-house testing under real-world temperature profiles to ensure dependable performance.

- Lightweight and Strong: Materials such as expanded polystyrene (EPS), foil-laminated linings and recycled fibre pads combine effective insulation with low weight, helping to reduce shipping costs.

- Flexible Formats: Hydropac’s insulation is available in flat pack liners, box sets, or as custom solutions made to order for specific payloads.

Sustainability without Compromise

Hydropac’s insulation systems are developed with recyclability and reusability in mind. We prioritise mono-material constructions, paper-based alternatives and fully recyclable polymers in many of our designs.

Our UK-based production facility allows us to reduce transportation emissions and tightly control quality. With careful engineering, we also reduce material waste at the source by cutting only what is needed for each product batch.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about High-Performance Cooling Insulation

What makes insulation “high-performance” in cold chain packaging?

High-performance cooling insulation refers to materials and designs that offer superior thermal resistance, helping maintain stable internal temperatures during transit. At Hydropac, this means using effective materials such as expanded polystyrene (EPS), foil-based reflective insulation, and recycled PET fibre. When combined with our ice packs, these solutions can maintain chilled or frozen conditions for over 48 hours, depending on configuration.

Which insulation materials are most effective for pharmaceutical shipping?

For pharmaceutical applications, closed-cell foam, EPS boxes, and gel ice packs are commonly used. These materials provide excellent thermal resistance and are lightweight yet durable. Our PharmaPac range uses validated packaging options ideal for maintaining strict temperature ranges required for vaccines, biologics, and diagnostic kits.

Are Hydropac’s cooling insulation products environmentally friendly?

Yes. Many of our products feature sustainable insulation materials, such as kerbside recyclable paper liners in EnviroCool, or PET-based fibres made from recycled plastic in RecycleAir. We also focus on lightweight designs to reduce energy consumption during transport and aim for full recyclability wherever possible.

How do ReflectiveAir and other foil-based insulations work?

Foil-based solutions like ReflectiveAir use radiant barrier technology. These insulations reflect heat away from the packaged goods instead of absorbing it, making them ideal for short-haul deliveries and summer conditions. Their lightweight structure adds minimal bulk, helping reduce shipping volume and cost.

Can high-performance insulation help reduce energy bills or environmental impact?

While Hydropac’s insulation is designed for transport and cold chain packaging, the same principles of thermal efficiency apply. Better insulation reduces the need for active cooling, cutting down on energy consumption during storage or distribution. This leads to lower carbon emissions and improved environmental outcomes, especially when paired with recyclable materials and smart logistics planning.