Trusted by leading companies

Vacuum insulated panels

- Advanced thermal insulation expertise

- System based cold chain solutions

- Informed, bespoke packaging design

High performance insulation for advanced cold chain packaging

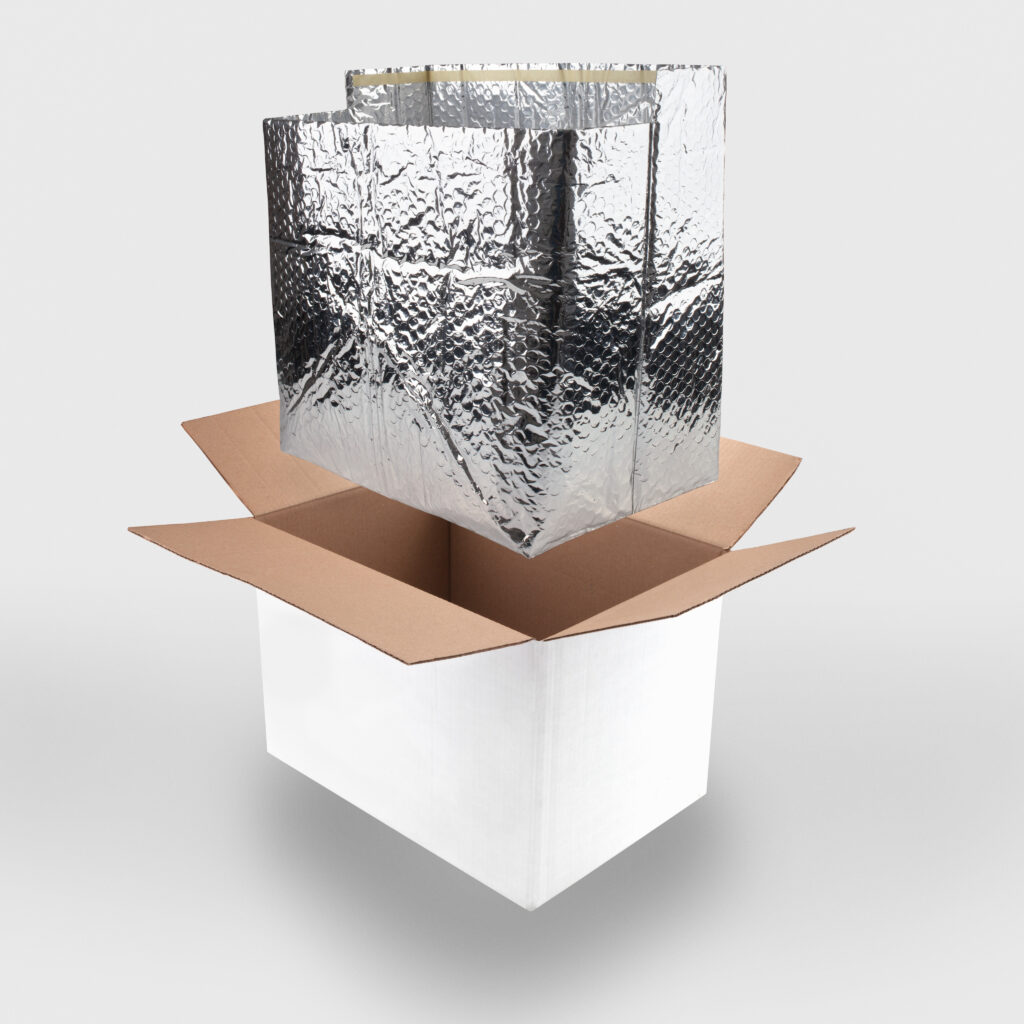

Vacuum insulated panels, often referred to as VIPs or Vacuum Insulation Panels, represent one of the highest performing insulation technologies available for temperature controlled packaging. Designed to minimise heat transfer through conduction, convection and radiation, VIPs deliver exceptional thermal insulation where space efficiency and extended temperature stability are critical. Within advanced cold chain packaging systems, they are used to support demanding food and pharmaceutical distribution scenarios where conventional insulation may not achieve the required performance.

At Hydropac, vacuum insulated panels are considered as part of specialist insulated packaging systems, evaluated alongside proven cooling elements such as ice packs, gel packs and phase change materials to support chilled and frozen distribution under controlled conditions.

Discover Vacuum insulated panels

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Where precision insulation supports critical temperature stability

VIPs are applied in temperature controlled packaging when insulation performance must be maximised within limited internal space. Their unique construction allows extremely low thermal conductivity and high insulation value compared to traditional materials such as polystyrene or rigid foam.

Unlike standard insulation, vacuum insulated panels rely on:

- Internal pressure reduction to limit heat transfer

- Advanced core materials to support structural stability

- Gas-tight barrier layers to maintain long term performance

This makes them particularly suitable for temperature sensitive pharmaceuticals, clinical materials and specialist cold chain applications requiring extended hold times.

How vacuum insulated panels achieve superior thermal performance

A vacuum insulated panel consists of a microporous core material, commonly based on fumed silica, enclosed within a multi-layer gas-tight film. This sealed envelope, often incorporating aluminium foil or metallised layers, prevents air ingress and significantly reduces thermal conductance.

Key insulating properties include:

- Extremely low thermal conductivity compared to conventional insulation

- High thermal resistance and R-value performance in thin profiles

- Reduced thermal bridging within insulated containers

- Improved protection against external temperature fluctuations

By limiting heat transfer through conduction, convection and radiation, VIPs help stabilise internal temperatures even under challenging ambient conditions.

Integration within temperature controlled packaging systems

Vacuum insulated panels are not used as standalone solutions. In cold chain packaging, they are integrated into insulated containers and combined with cooling media to form complete thermal management systems.

Typical packaging applications include:

- Pharmaceutical and healthcare shipments with strict temperature thresholds

- Clinical trial and life science materials requiring extended temperature control

- Low temperature and frozen applications where space efficiency is critical

- High value temperature sensitive goods with limited payload tolerance

When correctly integrated, VIPs can reduce the volume of cooling elements required while maintaining consistent temperature control throughout transportation.

Practical considerations for packaging applications

Despite their performance advantages, vacuum insulated panels require careful system design. The integrity of the vacuum is essential, meaning packaging must protect panels from mechanical stress, puncture or prolonged pressure.

Key design considerations include:

- Structural protection to maintain vacuum integrity

- Controlled placement to avoid thermal bridges

- Compatibility with ice packs, gel packs or phase change materials

- Balancing insulation performance with cost and operational practicality

At Hydropac, our expertise lies in assessing whether advanced insulation technologies such as VIPs are appropriate for a given cold chain challenge, and how they can be combined with scalable, proven packaging solutions.

A balanced approach to advanced thermal insulation

Vacuum insulated panels represent one option within a broader thermal insulation strategy. For many food and pharmaceutical applications, well designed insulated packaging paired with ice packs or gel packs delivers reliable, cost effective performance. Where temperature requirements become more demanding, VIPs may be considered as part of a bespoke temperature controlled packaging solution.

By understanding the physics of heat transfer, insulation performance and system integration, Hydropac supports informed decisions that protect product integrity, optimise thermal performance and maintain cold chain reliability.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about vacuum insulated panels

What are VIPs in temperature controlled packaging?

VIPs, or Vacuum Insulation Panels, are high performance insulation panels used in specialist temperature controlled packaging. They reduce heat transfer by using a vacuum sealed structure, which delivers very low thermal conductivity and high thermal resistance in a thin profile.

What are vacuum insulated panels made from?

A Vacuum Insulation Panel typically uses a microporous core material, commonly fumed silica, supported by fibres such as glass fibre or polyester fibres. The core is sealed inside a gas-tight film, often a multi-layer aluminium foil wrapper or metallised plastic film, to maintain the vacuum and preserve insulating properties.

How do VIPs improve thermal performance compared to polystyrene?

VIPs provide a much higher insulation value than polystyrene insulation at a fraction of the thickness. In practical terms, this means improved space efficiency, higher R-value performance, and reduced thermal bridging within insulated containers. The trade off is that VIPs require careful protection to prevent puncture and loss of vacuum.

Can VIP packaging be combined with gel packs or phase change materials?

Yes. VIP based systems are typically used as part of complete thermal management solutions, paired with gel packs, ice packs or phase change materials to maintain controlled temperature ranges. This combination is particularly useful for pharmaceutical and life science shipments where temperature stability is critical.

Are vacuum insulated panels always the best choice for cold chain shipping?

Not always. While VIPs offer exceptional thermal insulation, they are most suitable for high demand applications where space efficiency and extended hold times justify the added cost and handling requirements. For many food and standard pharmaceutical shipments, well designed insulated packaging combined with ice packs or gel packs can deliver reliable performance more efficiently.