Trusted by leading companies

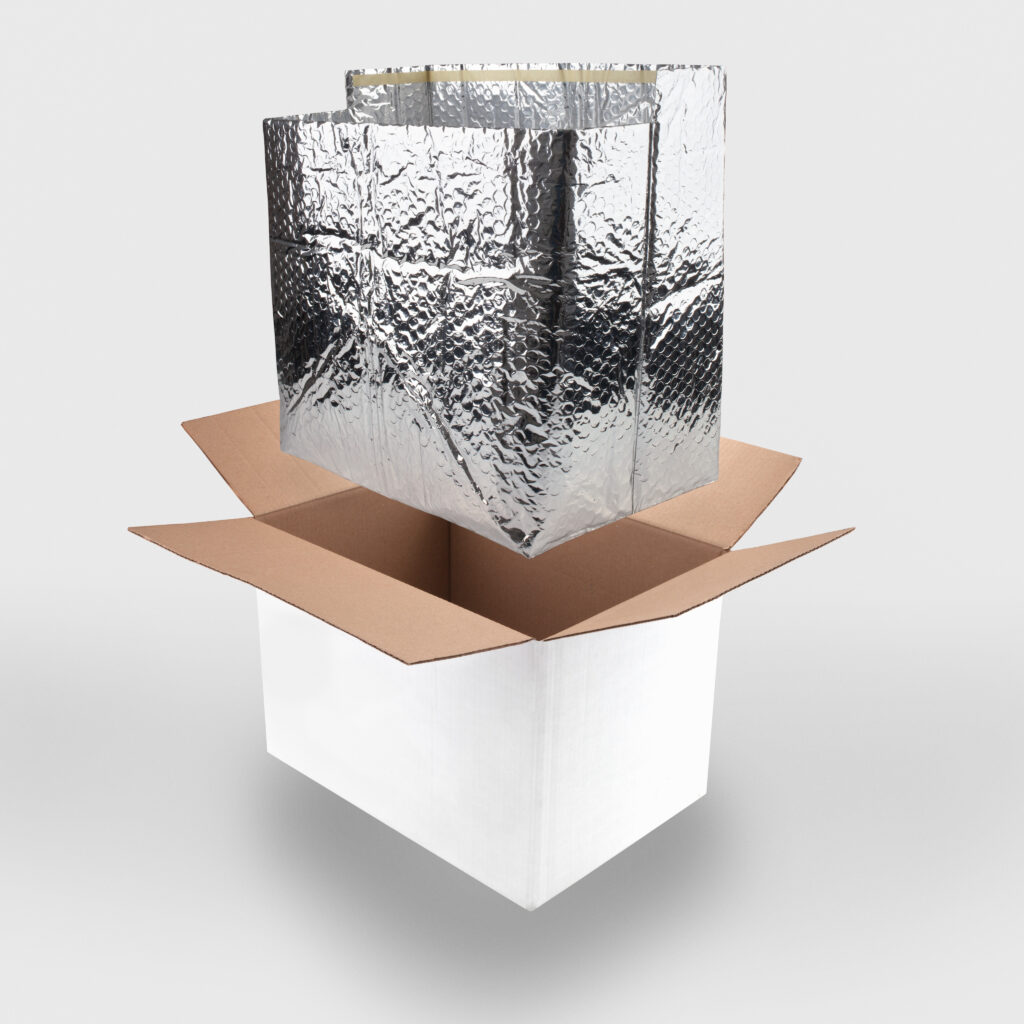

Thermal insulated packaging

- Engineered thermal performance

- Complete packaging and cooling systems

- Bespoke solutions for food and pharma

Protecting temperature sensitive goods with reliable insulation

Thermal insulated packaging is essential for maintaining stable temperatures throughout the cold chain. At Hydropac, we design and manufacture insulated packaging solutions that protect food, pharmaceuticals and other perishable goods during storage and transit. By combining effective insulation with ice packs and gel packs, our systems help reduce temperature fluctuations and safeguard product integrity. From chilled food distribution to pharmaceutical applications, our thermal insulated packaging delivers dependable performance while supporting hygiene, efficiency and sustainability across modern supply chains.

Discover Thermal insulated packaging

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Built to perform across demanding cold chain environments

Thermal insulated packaging must do more than simply surround a product. It needs to manage heat transfer, support consistent temperature ranges and integrate seamlessly with cooling elements. At Hydropac, our solutions are engineered as complete systems, combining insulation design with proven cooling technologies to support reliable cold chain performance.

Intelligent insulation design

The effectiveness of thermal insulated packaging starts with material choice and structural design. Hydropac offers a wide range of insulated containers and liners tailored to different temperature profiles and distribution challenges.

Our insulation solutions include:

- Insulated boxes and containers for chilled, refrigerated and frozen goods

- Polystyrene based and alternative insulation formats suited to specific applications

- Corrugated and composite structures that enhance thermal stability

- Liners and inserts designed to minimise heat ingress during transit

Each design is developed to balance thermal performance, packing efficiency and ease of use.

Integrated cooling for consistent temperature control

To maintain stable conditions, insulation is paired with carefully selected cooling elements. Hydropac manufactures a comprehensive range of ice packs and gel packs in house, using seal through water technology to ensure hygienic, leak resistant performance.

Our cooling solutions support:

- Chilled food and insulated food packaging applications

- Frozen and deep frozen distribution where extended protection is required

- Pharmaceutical products, vaccines and biological materials

- Laboratory and healthcare shipments requiring controlled conditions

Water based, gel based and hard shell ice packs can be tailored to suit specific temperature ranges and transit durations.

Sector focused packaging solutions

Different industries demand different levels of control. Through our FreshPac range, we support food sector requirements with packaging designed to protect freshness, quality and food safety. Our PharmaPac solutions are developed for pharmaceutical and life science applications, supporting temperature sensitive medicines and healthcare products.

Key advantages of our bespoke approach include:

- Packaging solutions matched to defined temperature requirements

- Custom sizing to reduce void space and optimise shipping efficiency

- Reliable thermal performance tested for real world distribution

- Sustainable material options to support environmental objectives

By combining insulation expertise with integrated cooling and bespoke design, Hydropac delivers thermal insulated packaging that supports dependable temperature control across food and pharmaceutical supply chains.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about thermal insulated packaging

What is thermal insulated packaging?

Thermal insulated packaging is designed to slow heat transfer and help maintain products within a required temperature range during storage and transport. It is commonly used for food, pharmaceuticals and other temperature sensitive goods that require protection throughout the cold chain.

How does thermal insulated packaging work?

It works by using insulating materials and structural design to reduce the impact of external temperatures. When combined with ice packs or gel packs, thermal insulated packaging helps stabilise internal conditions and minimise temperature fluctuations during transit.

Is thermal insulated packaging suitable for chilled and frozen products?

Yes. Thermal insulated packaging can be designed for chilled, refrigerated or frozen applications. The level of insulation and the type of cooling elements used are tailored to the required temperature range and expected transit time.

Can thermal insulated packaging be customised?

Absolutely. Hydropac offers bespoke thermal insulated packaging solutions, allowing sizes, insulation formats and cooling components to be matched to your specific product, temperature profile and distribution needs.

Is thermal insulated packaging a sustainable option?

Thermal insulated packaging can support sustainability goals when designed efficiently and paired with recyclable or reusable materials. Hydropac offers a range of solutions that balance thermal performance with reduced material use and responsible packaging choices.