Trusted by leading companies

Temperature controlled logistics

- Certified cold chain expertise

- Sustainable insulated packaging

- Proven temperature reliability

The Role of Precision in Modern Supply Chains

Temperature controlled logistics plays a crucial role in ensuring that temperature-sensitive products such as pharmaceuticals, fresh food, and biological materials maintain their integrity throughout storage and transport. By using advanced temperature regulation systems and specialised packaging, businesses can guarantee that their goods remain within required temperature ranges from origin to destination. Hydropac supports this critical process with a range of expertly engineered packaging products designed for dependable temperature control. From gel packs and insulated boxes to full cold chain solutions, Hydropac enables distributors and manufacturers to meet regulatory requirements and deliver products safely, sustainably, and with precision.

Discover Temperature controlled logistics

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Reliable Temperature Control Across Every Stage

In the pharmaceutical, food, and biotechnology sectors, maintaining precise temperature ranges is not just good practice – it is a regulatory requirement. Temperature controlled logistics ensures that sensitive goods remain stable during transit, preventing temperature excursions that can lead to spoilage, inefficacy, or compliance issues. Whether products need to stay chilled, frozen, or ambient, Hydropac provides the specialised solutions that make consistent temperature control achievable.

Packaging That Protects Integrity

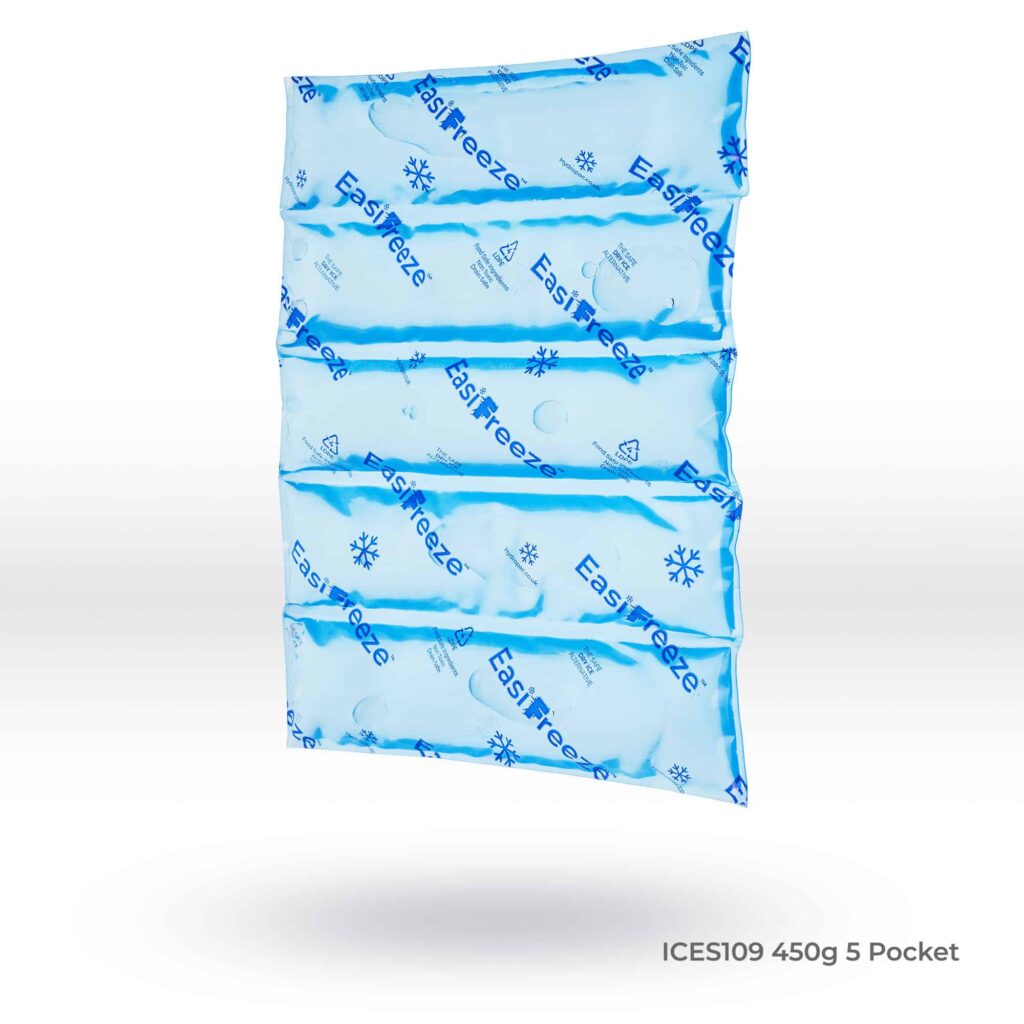

Hydropac’s packaging solutions are developed to uphold strict temperature parameters throughout the supply chain. Our PharmaPac range, featuring gel ice packs and polystyrene boxes, is ideal for pharmaceutical and medical applications, while our FreshPac systems ensure food products arrive fresh and safe for consumption.

These systems deliver reliability through:

- Validated performance: Packaging tested under real-world conditions to meet UK and EU regulations.

- Eco-friendly materials: Recyclable, drain-safe and reusable components for sustainable cold chain management.

- Precision engineering: Manufactured using our patented seal through water technology for leak prevention and hygiene assurance.

Meeting Cold Chain Compliance and Sustainability Goals

In modern supply chains, compliance and sustainability go hand in hand. Pharmaceutical distribution, for instance, is governed by GDP (Good Distribution Practice) guidelines, requiring that temperature monitoring and control remain traceable at every stage. Hydropac’s solutions complement these requirements by offering products designed for consistent performance, lower waste, and full recyclability.

Our approach aligns with evolving global standards for:

- Temperature validation and monitoring

- Quality assurance and product traceability

- Environmentally responsible packaging systems

Why Choose Hydropac for Temperature Controlled Logistics?

- Tailored cold chain systems for pharmaceuticals, food, and biotechnology.

- Certified quality ensuring regulatory compliance and safe transit.

- Sustainable innovation supporting both performance and environmental responsibility.

For reliable and sustainable cold chain performance, Hydropac’s solutions provide the foundation for safe and compliant temperature controlled logistics across industries.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about Temperature Controlled Logistics

What is temperature controlled logistics?

Temperature controlled logistics refers to the process of storing, transporting, and handling goods that must be kept within specific temperature ranges. This includes products such as vaccines, insulin, dairy, seafood, and other temperature-sensitive materials. It relies on insulated packaging, refrigerants like gel packs, and continuous temperature monitoring to maintain product quality and compliance.

Why is temperature control important in pharmaceutical logistics?

Pharmaceutical products such as vaccines and biologics are highly sensitive to temperature fluctuations. Even small deviations can compromise their efficacy or safety. Reliable cold chain systems ensure that these products remain within the approved range from manufacturing through delivery, protecting both compliance and patient safety.

How does Hydropac support cold chain operations?

Hydropac offers high-performance packaging solutions specifically engineered for cold chain logistics. Our PharmaPac and FreshPac ranges include gel packs, insulated boxes, and recyclable packaging materials that provide stable temperature control for pharmaceuticals and food products throughout transit.

Are Hydropac’s packaging products recyclable and sustainable?

Yes. Sustainability is a key focus of Hydropac’s design and manufacturing process. Many of our solutions are made from recyclable materials and water-based gels that are drain-safe and environmentally friendly. We continuously innovate to reduce waste and enhance the circularity of our packaging.

What industries benefit most from temperature controlled logistics?

Industries such as pharmaceuticals, biotechnology, healthcare, and food production rely heavily on temperature controlled logistics. These sectors handle products that require precise temperature regulation to ensure safety, freshness, and regulatory compliance. Hydropac’s tailored solutions serve all of these sectors effectively.