Trusted by leading companies

Temperature controlled insulation

- Consistent Thermal Performance Across the Cold Chain

- Integrated with Complete Temperature-Controlled Packaging Systems

- Informed, bespoke packaging design

Reliable Thermal Protection for the Cold Chain

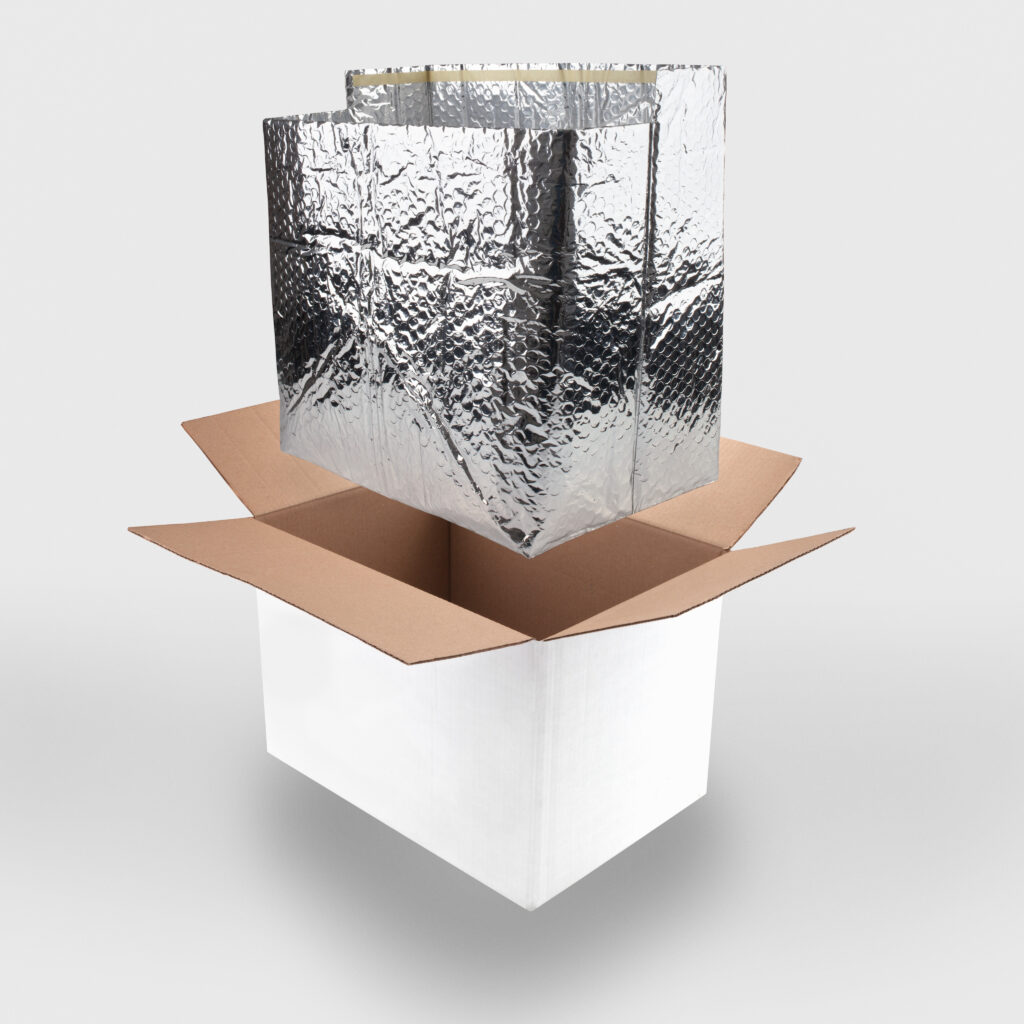

Temperature controlled insulation is essential for protecting temperature sensitive goods during storage and transit. It forms the foundation of effective cold chain packaging by reducing heat transfer and maintaining stable internal conditions. Hydropac develops high performance insulation solutions designed for food, pharmaceutical and life science applications where thermal reliability is critical. Through carefully selected insulation materials and proven packaging designs, temperature fluctuations caused by external conditions are minimised. Combined with compatible ice packs and gel packs, these insulation systems help safeguard product quality, support regulatory compliance and ensure goods arrive in optimal condition.

Discover Temperature controlled insulation

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Advanced Insulation Solutions for Temperature Sensitive Shipments

Temperature controlled insulation plays a vital role in managing heat transfer during transit. Whether goods are exposed to warm ambient conditions or cold air during distribution, insulation must reduce the effects of conduction, convection and radiation. Hydropac develops insulation solutions that provide reliable thermal performance across a wide range of cold chain applications, from food delivery to pharmaceutical logistics.

How Temperature Controlled Insulation Works

Effective insulation slows the movement of heat into or out of a package. By limiting thermal conductivity and air movement, internal temperatures remain within the required range for longer periods.

Key principles include:

- Reducing heat transfer caused by external temperature changes

- Minimising air leakage within insulated packaging systems

- Creating a thermal barrier that supports stable product storage temperatures

When combined with ice packs or gel packs, insulation helps extend cooling duration and improves overall temperature stability during shipment.

Insulation Materials Designed for Cold Chain Packaging

Different applications require different insulation properties. Hydropac insulation solutions are selected for performance, consistency and practicality within temperature controlled packaging.

Common insulation formats include:

- Thermal liners for insulated shipping boxes

- Moulded insulation inserts for consistent packout configuration

- Lightweight insulating sheets that maximise internal space

- Materials designed to balance thermal performance with recyclability

These solutions are used across FreshPac and PharmaPac packaging systems to support chilled, frozen and temperature sensitive goods.

Supporting Food and Pharmaceutical Applications

Temperature controlled insulation is critical in both food and pharmaceutical distribution. Insulation must maintain strict temperature ranges to protect product integrity, reduce spoilage and support regulatory requirements.

Applications include:

- Chilled and frozen food delivery

- Pharmaceutical shipments requiring controlled temperature ranges

- Transport of temperature sensitive medical and life science products

By maintaining stable conditions, insulation helps reduce the risk of bacterial growth, degradation or loss of efficacy during transit.

Sustainable and Efficient Thermal Performance

Sustainability is an important consideration in modern cold chain packaging. Many insulation solutions are designed to reduce material usage while maintaining strong thermal performance. Recyclable components and efficient designs help support responsible disposal and improved environmental outcomes.

Temperature controlled insulation solutions can also reduce the need for excessive refrigerants, helping to improve energy efficiency across the supply chain while maintaining reliable thermal protection for sensitive shipments

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about Temperature Controlled Insulation

What is temperature controlled insulation?

Temperature controlled insulation refers to packaging materials and systems designed to reduce heat transfer and maintain stable internal temperatures during storage and transport. It is a key component of cold chain packaging for food, pharmaceutical and other temperature sensitive goods.

How does insulation help maintain temperature during transit?

Insulation slows the transfer of heat caused by external conditions. By limiting conduction, convection and air movement, internal temperatures remain more stable, allowing ice packs and gel packs to perform more effectively over longer periods.

Which products require temperature controlled insulation?

Many products rely on temperature controlled insulation, including chilled and frozen foods, pharmaceuticals, medical samples and other temperature sensitive materials. Any product with a defined storage temperature benefits from effective insulation during shipment.

Is temperature controlled insulation used on its own?

Insulation is typically used as part of a complete packaging system. It works alongside ice packs, gel packs and insulated containers to maintain the required temperature range throughout the cold chain.

Are insulation solutions suitable for sustainable packaging goals?

Yes, many insulation solutions are designed with sustainability in mind. Efficient designs, reduced material usage and recyclable components help balance strong thermal performance with environmental responsibility.