Trusted by leading companies

ReflectiveAir insulation

- Superior Thermal Efficiency

- Lightweight Recyclable Design

- Moisture-Resistant Performance

Advanced Thermal Protection for Temperature-Controlled Packaging

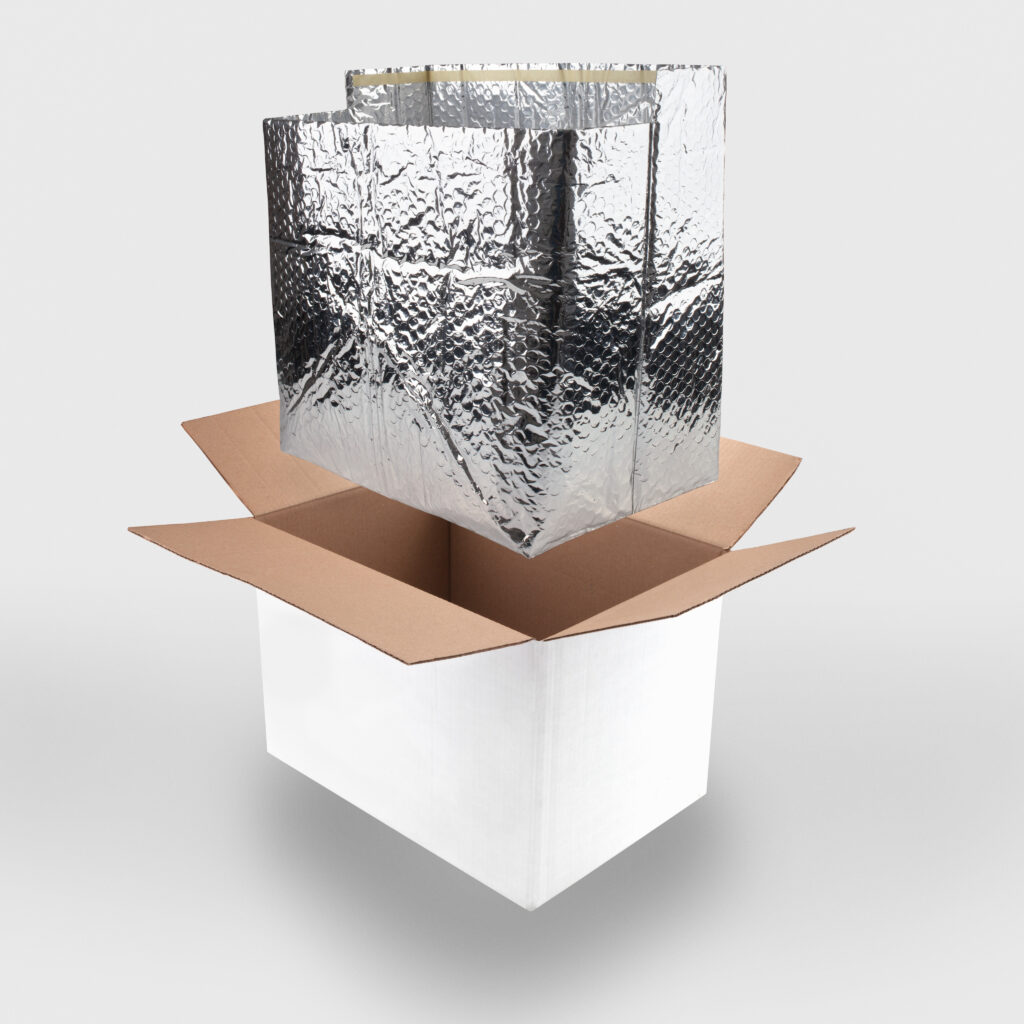

ReflectiveAir insulation is a high-performance thermal material developed by Hydropac to improve the efficiency and reliability of temperature-controlled packaging. Designed as part of the FreshPac range, it uses reflective foil layers to minimise heat transfer through radiation, conduction and convection. The result is exceptional temperature stability, making it ideal for transporting fresh food, pharmaceuticals and other temperature-sensitive goods. ReflectiveAir helps maintain precise internal conditions, whether used in chilled or frozen applications. Its lightweight, recyclable design supports sustainable logistics while ensuring consistent insulation performance throughout the cold chain.

Discover ReflectiveAir insulation

Hydropac isn’t just packaging; it’s a revolution of quality, innovation, and sustainability. Join us on this exciting journey to redefine packaging excellence.

Innovative Design for Thermal Efficiency

At Hydropac, ReflectiveAir insulation represents the perfect balance between science, sustainability and performance. Developed as part of the FreshPac family, it has been engineered to reduce heat transfer and protect perishable items from external temperature fluctuations. Using multiple reflective layers and an insulated air space, it significantly improves thermal resistance and ensures that goods remain safe, fresh and stable during transit.

ReflectiveAir insulation is a versatile material that combines reflective foil, polyethylene and air cells to form an effective barrier against heat conduction and radiation. This design has been rigorously tested within our Climate Chamber, allowing precise analysis of insulation performance under real-world conditions.

The Science Behind ReflectiveAir

Our insulation technology is based on principles of radiant heat reflection, vapour control and airflow management. ReflectiveAir provides outstanding protection against heat gain or loss in packaging systems designed for chilled, frozen and ambient-sensitive products.

Key benefits include:

- Exceptional thermal performance, maintaining temperature consistency throughout transport.

- Lightweight composition, reducing overall package weight and transport costs.

- Recyclable materials, supporting sustainability and reducing environmental impact.

- Moisture resistance, preventing condensation or degradation within the packaging layer.

- Compliance with Building Regulations and recognised standards for thermal insulation performance.

Hydropac has designed ReflectiveAir to integrate seamlessly with complementary systems such as EnviroCool and RecycleAir, delivering complete cold chain protection. Together, these solutions ensure that every package achieves the right balance between temperature control, product safety and eco-conscious design.

Practical Applications Across Industries

ReflectiveAir insulation offers reliability across multiple sectors. In food packaging, it maintains product freshness during e-commerce deliveries, meal kit shipments and grocery distribution. In pharmaceutical logistics, it supports the secure transport of vaccines and temperature-sensitive medicines where even minor fluctuations can compromise quality.

ReflectiveAir can also be used in reusable box liners, insulated pallets and shipping systems that demand consistent temperature control. Explore related products like FreshPac ReflectiveAir System and FreshPac to discover how Hydropac solutions can enhance cold chain efficiency and sustainability.

Engineered for a Greener Future

Sustainability is integral to Hydropac’s innovation. ReflectiveAir insulation is made from recyclable materials that can be reintroduced into the production cycle, reducing waste without compromising performance. Its lightweight yet durable structure minimises energy use in storage and transport, helping customers meet environmental goals while maintaining the highest insulation standards.

Hydropac continues to set new benchmarks for cold chain reliability through technology-driven design, rigorous testing and commitment to eco-friendly materials, ensuring every shipment stays perfectly protected, every time.

Contact us directly

We are ready to answer all your questions and help you find the perfect solution for your cold chain transport.

From issue to a customised cooling solution

In this way we help you to guarantee the quality and safety of food products under all circumstances.

Mass production

Transport

End user

FAQ's about ReflectiveAir Insulation

What is ReflectiveAir insulation used for?

ReflectiveAir insulation is designed to maintain stable temperatures in temperature-controlled packaging. It reflects radiant heat, limits conduction, and reduces convection within the package, making it ideal for shipping fresh food, frozen goods, and pharmaceutical products that require consistent thermal protection.

How does ReflectiveAir differ from other insulation materials?

Unlike traditional foam or polystyrene insulation, ReflectiveAir uses a multi-layer reflective foil structure that traps air and minimises heat transfer. This makes it lightweight, moisture-resistant, and recyclable while delivering strong thermal performance. The technology has been validated through testing in Hydropac’s Climate Chamber, ensuring reliability under real transport conditions.

Is ReflectiveAir insulation recyclable?

Yes. ReflectiveAir insulation is made using recyclable materials that can be repurposed after use. It provides an eco-friendly alternative to conventional insulation products, helping businesses reduce waste and align with sustainability goals without compromising on temperature control.

Can ReflectiveAir insulation be used with other Hydropac systems?

Absolutely. ReflectiveAir is part of the FreshPac product family and works seamlessly with Hydropac’s other insulation and cooling systems such as EnviroCool and RecycleAir. Together, these solutions create a complete cold chain packaging system suitable for food, pharmaceutical and logistics applications.

What makes ReflectiveAir a reliable choice for cold chain logistics?

ReflectiveAir combines excellent thermal resistance with moisture protection and durability. Its advanced foil layers provide a high reflectivity surface, reducing radiant heat transfer while maintaining insulation efficiency. Used across various Hydropac systems, it ensures that products stay at the correct temperature, supporting both food safety and pharmaceutical compliance.